Mold Inserts include multi-purpose post.

Press Release Summary:

Master Unit Die (MUD) Enhanced Series Mold Inserts have guide ejection system design, maximizing available insert core and cavity surface area. Guidepost retains and guides ejection system, and provides support without additional support pillars. Inserts are available in popular 08/09 insert thicknesses. They come with 4 leader pins, bushings, and return pins. Parting line plates are finish-ground and bolted to ear plates on laminated construction mold inserts.

Master Unit Die (MUD) Enhanced Series Mold Inserts have guide ejection system design, maximizing available insert core and cavity surface area. Guidepost retains and guides ejection system, and provides support without additional support pillars. Inserts are available in popular 08/09 insert thicknesses. They come with 4 leader pins, bushings, and return pins. Parting line plates are finish-ground and bolted to ear plates on laminated construction mold inserts. Original Press Release:

Master Unit Die's New Enhanced Series Mold Inserts Feature Multi-Purpose Post To Provide Greater Cavity and Core Surface Area

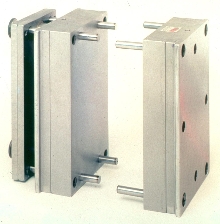

April 2002 - New Master Unit Die (MUD) Enhanced Series Mold Inserts optimize moldmaking efficiency for users of quick-change interchangeable mold insert systems. The new mold inserts feature a streamlined guided ejection system design. This configuration maximizes available insert core and cavity surface area, provides more room for pockets, and offers additional clamping surface area for faster, easier machining setup. Enhanced Series Mold Inserts are compatible with the MUD Quick-Change System (QCS) U Frame to provide a flexible solution to higher productivity and lower mold tooling costs.

A multi-purpose guidepost retains and guides the ejection system, and provides support without the need of additional support pillars. Enhanced Series Mold Inserts come installed with four leader pins, bushings, and return pins. Tapped holes are provided for insert installation/removal. Parting line plates are finish-ground, and are bolted to ear plates on laminated construction mold inserts. Ejector plates are bolted together for maximum convenience.

MUD Enhanced Series Mold Inserts are available in the most popular 08/09 insert thicknesses and steel grades for same-day shipment. Ejector plates are available in an optional 0.480-in. thickness at no additional charge.

For other standard sizes and virtually any steel grade, Enhanced Series Mold Inserts have the same fast delivery as all MUD quick-change system products, typically less than one week.

Master Unit Die, a D-M-E company, developed its concept for Quick-Change over 40 years ago to meet the parallel challenges of increasing productivity and decreasing cost. This tooling approach to injection molding offers mold makers and plastic manufacturers a number of competitive advantages. These include lower tool costs and faster production changeovers, ideal for just-in-time scheduling.

The MUD Quick-Change Systems use standard frames that remain fixed in the injection molding machine. The mold inserts can be quickly changed, making the system ideal for short production runs of multiple parts. Mold makers need only construct the core, cavity and ejection portions of the mold, which can reduce mold construction cost by as much as 65%. This clever approach also offers mold makers and molders the competitive advantages of quicker mold delivery, faster initial setup, faster production changeovers, minimum purging, and easy maintenance and repair.

In production, MUD quick-change systems provide unique advantages for molders. The primary benefit is rapid mold change. Set-up of the mold is reduced to installing the parts, clamping them to the frame, and connecting the cooling/heating

lines. This usually takes five minutes or less, and can result in a 75% saving in set-up time, enabling short, efficient production runs in JIT operations. Maintenance and storage of the mold is also easier, given the lighter weight of the insert set compared to an entire mold.

HOT RUNNER SYSTEMS - MOLD BASES - MACHINING SERVICES - MOLD & DIE COMPONENTS - TOOLS - SUPPLIES - TECHNICAL SERVICES

D-M-E Company; 29111 Stephenson Highway; Madison Heights, MI 48071; Tel 248/398-6000; Fax 248/398-6174