Major Tool & Machine adds Large-Part Production Capacity with Order for MAG Machine Tools and Retrofit of Mill/Turn Gantry

Share:

New machines include MAG's VTC 2500 and U5 XL 2500 universal portal mill with turning capabilities. Massive DSI mill/turn machine will also be retrofitted with new MAG U6 cross saddle and ram, multiple cutting heads, and Siemens 840D sl CNC

ERLANGER, KY – Major Tool & Machine lives up to its name with a multi-million-dollar order for large-part machining systems from MAG IAS that includes a new VTC 2500, a new U5 XL 2500 universal portal mill with turning capabilities, and a rebuild/retrofit of a DSI mill/turn gantry machine. In addition to milling, the U5 will provide large-part turning with an integrated 4-meter (13 ft) rotary table. Major Tool's existing DSI machine will be retrofitted with a new cross saddle and ram from the MAG U6 line, along with five interchangeable cutting heads and Siemens 840D sl CNC. Scheduled for completion in 2015, the machines will be delivered to, and retrofit work done at, Major Tool's 500,000-sq-ft climate-controlled campus, which serves the nuclear, aerospace, energy and general industrial markets.

Indianapolis-based Major Tool & Machine is one of North America's largest contract producers of massive fabrications and machined parts, serving elite companies and agencies with products and services that meet the highest industry requirements. Its quality certifications include AS9100 and ISO 9001, as well as multiple stamps for production and inspection of pressure vessels, boilers and nuclear equipment. "Our niche is very large parts made of exotic materials, such as Inconel®, Waspalloy®, Hastelloy®, and similar metals," said Steve Weyreter, Chairman and CEO of Major Tool. "We are one of the few North American shops that can turn parts as large as 43 feet in diameter, and we combine this with certified capabilities for welding and fabrication with exotic materials."

According to Weyreter, the new U5 machine will initially replace production capacity during the rebuild of Major Tool's massive DSI gantry mill/turn machine. "This is an extremely complex project that involves much more than simply adding machine tools, because it is critical that we maintain our large-part mill/turn capacity when the DSI machine goes offline," he said. "Part of our reputation is based on the depth of our capacity, so coordination and timing are vital when we take a critical machine offline. For a complex project requiring this level of management, engineering and technical resources, we preferred to work with a domestic source, and we have a long, successful history with MAG. This will also be a joint project to a great extent where our own staff will be heavily involved in the work."

Newest/largest U5 portal mill introduced

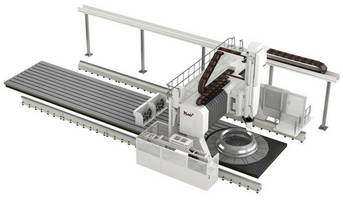

The rail-type U5 XL 2500 will introduce the newest and largest model of the U5 portal mill series, continuing the expansion of the Cincinnati U5 line that was launched more than a decade ago. Major Tool's U5 XL 2500 will be equipped with a 2.5-m (8.2 ft) Z-axis ram and multiple automatically changed cutting heads for five-axis and complex-geometry machining of large, tall parts. Configured with 22 m (72 ft) of X-axis rail, the machine's X range can be lengthened in 3.6 m (12 ft) increments. Y-axis range is 5,000 mm (196.85 inches). Machining heads purchased by Major Tool include a turning head with Sandvik Coromant® Capto C8 tool interface, and 5-axis gimbal, vertical and horizontal heads with CAT 50 Big Plus tool interface. Dual-range 52-kW (70 hp) spindles enable aggressive cutting in difficult materials. MAG will configure the machine for integration of a 4-m (13 ft) rotary table to be purchased by Major Tool, and then install the table and drive. Upon acceptance of the U5 machine, MAG technicians will begin rebuild/retrofit of the DSI in Major Tool's plant.

As part of the rebuild/retrofit of the DSI (D̦rries Scharmann) mill/turn gantry machine, MAG will adapt a new cross saddle Рincluding a U6 2.5-meter ram with integrated C axis Рto the machine's existing cross rail. The saddle and ram modules will be unit-assembled at MAG's Hebron, KY, plant, complete with utilities, plumbing and wiring, prior to shipment and installation. The ram has a robust cross section of 697 mm (27.4 in) by 769 mm (30.3 in) to withstand high cutting forces during heavy metal removal. "These new modules need to interface precisely with the existing way/bearing systems and drives on the DSI machine, so it's a significant engineering and installation challenge," said Randal Von Moll, MAG Director of Technical Sales. Five interchangeable U6 cutting heads for the machine include vertical milling (97 kW/130 hp), vertical offset (37 kW/50 hp), right-angle milling (97 kW/130 hp), 5-axis gimbal (52 kW/70 hp) and turning.

The retrofit also includes a five-position head changing stand, new distance-coded X-Y-W scales, a new 60-pocket tool changer and Renishaw spindle probe and laser toolsetter. Distance-coded scales minimize the axis travel (and time) needed to re-home, aiding in shortened cycle times, according to Von Moll. The machine's 6-m (19.7 ft) rotary table will be equipped with a new electric motor/drive as part of the Siemens CNC retrofit, then tuned to make it position more quickly and accurately. As a final step, MAG service engineers will check and correct the machine's geometric alignments, calibrate the axes, and conduct circle/diamond/square and horsepower test cuts. "The updated machine modules, new CNC, servomotors and drives will result in machine performance that will exceed what this machine could do when it was new," Von Moll added.

The MAG (Giddings & Lewis) VTC 2500 is engineered to make short work of large-part turning for a variety of industries, offering multiprocessing machining capabilities with high-end specifications like ±1,560 mm (61 in) of full X-axis travel left/right of center, 2,755 mm (108.5 in) rail height, 2,700 mm swing and 84-kW (112.6 hp) table drive. The VTC 2500 accepts modular Capto C8 tooling. Major Tool added versatility to the machine with a 90-degree live spindle and an angular indexing head, both housed in the tool magazine for automatic changing into the new MAG SL 250 adaptor.

About MAG

MAG Americas is a leading machine tool and systems company serving the durable goods industries worldwide with productive manufacturing solutions for metal cutting and processing composite materials. With a strong foundation based upon renowned brands such as Cincinnati, Forest Liné and Giddings & Lewis, MAG offers unmatched expertise and innovation. From four facilities in North America and two in France, MAG offers a wide range of precision machine tools and engineering services for the most demanding applications in the aerospace, heavy equipment, oil/gas, renewable energy and general industrial market sectors. A global support network ensures comprehensive, 24/7 customer care.

For more information about MAG, please visit: www.mag-ias.com

Vicki Rye Â

MAG IAS, LLCÂ Â Â Â

859 534 4526Â Â

vicki.rye@mag-ias.com Â