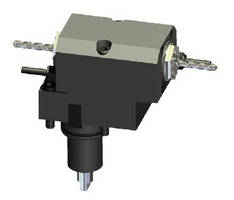

Live Tooling features double ended configuration.

Press Release Summary:

Available for Doosan twin-spindle and sub-spindle lathes, Live Tooling features double-ended ER-25 collet right angle configuration, which is offset to BMT55 turret location, allowing for extra clearance on back of turret. Pressure-lubricated design uses coolant to maintain temperature control to precision angular contact ball bearings for optimal manufacturing tolerances. By using precision live tooling on CNC lathes, users can eliminate secondary milling and drilling operations.

Original Press Release:

Double Ended Live Tooling for Doosan BMT Lathes

Planet Products Corporation introduces a new live tool for Doosan twin-spindle and sub-spindle lathes. The tool features a double-ended ER-25 collet right angle configuration which is offset to the BMT55 turret location. The offset configuration allows for extra clearance on back of the turret, while allowing increased tool length on sub spindle side.

An optional speed up transmission increases tool rpm from a standard turret for high speed, small tool machining operations.

Live Tooling from Planet features a patented coolant cooled and pressure lubricated design, which maintains temperature control to the precision angular contact ball bearings. Consistent bearing temperature allows for closer manufacturing tolerances resulting in more reliable operation, and longer service life.

Use of precision live tooling on CNC lathes can eliminate secondary milling and drilling operations, allowing many parts to be completed in a single operation.

Planet Products Corporation is a precision manufacturer specializing in machine tool accessories located in Cincinnati, Ohio. Contact Garth Dexter, General Manager 513-984-5544Â www.planet-products.com .