Linear Actuators satisfy medium to high duty actuation.

Share:

Press Release Summary:

Rolaram Linear Actuators withstand 5-400 kN loads at speeds of up to 7000 mm/min as standard. Three types of lead screws can be used: machine, ball, and roller. Roller screw meets high duty aspect while keeping unit compact. Unit provides high dynamic load carrying capacity along with almost no axial backlash or wear. Electric motor can be mounted in line, at right angles, or parallel to ram allowing actuator to fit into most spaces without special modifications.

Original Press Release:

Rolaram - A Powerful Linear Motion Solution

Power Jacks Rolaram linear actuators are designed to satisfy medium to high duty actuation applications with 5kN to 400kN loads at speeds of up to 7000 mm/min as standard.

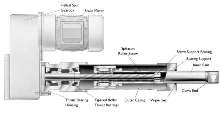

To meet the performance range three types of lead screw can be used; machine screw (low duty) ball screw (medium duty) and roller screw (medium to high duty). The roller screw design is essential to meet the high duty aspect while keeping the unit compact and providing the customer with a practical working life. Roller screws in general have higher dynamic load carrying capability than ball screws for a given working envelope. The Rolaram uses Power Jacks own Spiracon design, which has a high efficiency mechanism, with a high dynamic load carrying capacity along with almost no axial backlash or wear.

The electric motor can be mounted in line, at right angles or parallel to the ram. This allows the actuator to fit into most application spaces without special modifications. The mounting options for the units are equally varied and flexible and include the classic trunnion to clevis and double clevis arrangements.

Rolarams are successfully providing customers with a real alternative to hydraulics even when operated to the extreme with some units operating on a continuous cycle basis 24 hours a day and others operating in harsh environments.