Lightweight Modules facilitate tape-and-reel component loading.

Share:

Press Release Summary:

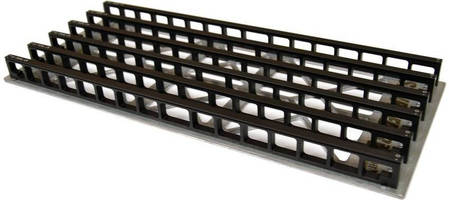

Designed for OEM automated tray towers, StripFeeder Lightweight includes 6 skeletonized rails and low-mass base plate. Rails, available for 0.25, 0.50, 0.75, and 1.125 in. pocket depths, can be removed and mounted to accommodate array of tape sizes in same feeder. Rails can also be removed to accommodate components up to 120 mm tape width. Mechanical lock-spring holds tape in place by sprocket hole for part registration and repeatable pick-and-place applications.

Original Press Release:

Count On Tools Inc. Introduces the StripFeeder Lightweight Kit

GAINESVILLE, GAÂ – Count On Tools, Inc. (COT), a leading provider of precision components and SMT spare parts, has released a new version in its award-winning line of StripFeeder products – the StripFeeder Lightweight. Increased demand for use of the StripFeeder platform in OEM automated tray towers prompted the need for a low-mass version to accommodate machine weight limits on tray capacity. The StripFeeder Lightweight system allows customers to take advantage of the StripFeeder platform in these specific applications.

The StripFeeder Lightweight includes six skeletonized rails and COT’s new low-mass base plate. The skeletonized design reduces carrier tray weight by 40-50 percent. StripFeeder Lightweight Rails are available for in 0.25" (6mm), 0.50" (12mm), 0.75" (19mm), and 1.125" (28mm) pocket depths.

All StripFeeder systems feature removable rails that can be mounted to accommodate a wide array of tape sizes in the same feeder. Unlike fixed width tape carrier trays, the StripFeeder can be adjusted by removing the rails and re-positioning them on the base plate at the desired width (4mm pitched pattern). The rails align with precision pin locaters and lock down tightly with magnets to guarantee a stable, repeatable application. All StripFeeder Lightweight Rails also feature a mechanical lock-spring to hold the tape in place by the sprocket hole for part registration and repeatable pick-and-place applications. This means the user only has to teach the pick-up location one time and consistently reload the unit with the same parts over and over for longer runs.

This innovative rail design holds the components securely in the machined tracks to prevent parts from being miss-picked, flipped in the pocket or lost. Customers also can remove rails to accommodate larger components up to 120mm tape width. The StripFeeder system is compatible with most types of SMT equipment. The StripFeeder systems are a cost-effective way to load many components, including odd-form and custom components, without having to purchase expensive feeders. The quick-to-assemble, easy-to-install modules are designed for rapid loading of tape-and-reel components on existing SMT pick-and-place equipment. Additionally, the trays enable fast changeover between product runs without unloading from the machine.

The StripFeeder Lightweight will be officially launched during the IPC APEX EXPO in Las Vegas this March. Customers can stop by the Count On Tools booth (#2801) to see the new product.

For more information about Count On Tools’ products and services, visit www.cotinc.com.

About Count On Tools Inc.

Count On Tools Inc., a precision component manufacturer specializing in all aspects of the machining industry, has been setting new performance standards in the SMT pick-and-place nozzle market since 1991. As the ORIGINAL source for high-quality, low-cost vacuum placement nozzles and associated consumables, they have pioneered with world-class development and process engineers that combine to ensure that innovation and competitiveness is applied to all of its extensive product range. The company also stands behind its products 100% with a full warranty. Count On Tools’ products are in use at many of the world's leading electronics manufacturing companies. Proven engineering expertise, coupled with the latest in design and manufacturing technology, has allowed the company to simplify the complexities of the industry and deliver a solution to its customers.

The company also maintains and supports a strong position in the hand tool industry, offering the highest quality hand tools in the world with PB Swiss Tools. These tools compliment any and all high-tech environments requiring optimum performance from both their equipment and technicians.