Additive Manufacturing Systems

Latest 3D Metal Printer Uses Laser Powder-Bed Fusion Process

Press Release Summary:

- Integrated with Flow™ pre-print software and Assure™ quality control software

- Offered in 600 mm. diameter x 550 mm. height build volume and 8 lasers with 1,000 W each

- Utilizes optical-train design, recoater technology, gas-flow technology, and metrology

Original Press Release:

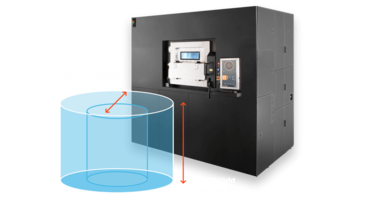

VELO3D Announces Sapphire® XC, Large Format 3D Metal Printer with up to 5X Productivity Improvement and 75% Cost Reduction

13 advance orders for new additive manufacturing system already received

CAMPBELL, Calif. - October 20, 2020 —VELO3D, an innovator in digital manufacturing, announced the expansion of its systems portfolio to include Sapphire XC, an “Extra Capacity” large-format printer that will increase production throughput by 5X and reduce cost-per-part by up to 75%, when compared to the existing Sapphire system.

The company also announced plans to roll-out Sapphire Gen 2, which will be a software and hardware upgrade to the current system. Users can expect an improvement of anywhere between 10-50% in productivity and part-cost metrics when compared to the current Sapphire system. The Sapphire Gen 2 upgrade will be available to retrofit on all installed systems starting in Q2 2021.

The Sapphire product family now includes Sapphire Gen 2, the 1-meter tall Sapphire 1MZ and Sapphire XC—all using the laser powder-bed fusion (LPBF) process with patented capabilities to print without consideration of support structures. Sapphire systems specifically address the aerospace, power generation, and energy markets' unmet needs for quality-assured manufacturing of uncompromised geometries.

"Printing larger parts without the additive manufacturing constraints of support structures is highly attractive to many industrial end-users,” said Benny Buller, founder, and CEO of VELO3D. “For the first time, customers will be able to 3D-print uncompromised geometries, with the highest confidence in part quality, in a large format system. Quality assurance with large scale components is critical because the economic impact of failed builds is very significant. We have demonstrated that our integrated solution is capable of producing a greater yield of high-quality parts, and that foundational technology will transfer to our new Sapphire XC."

Sapphire XC Features

- Larger build volume: Build volume 600mm x 550 mm (compared to 315mm x 400 mm in Sapphire)

- Higher productivity for production: 8 lasers x 1,000W each (compared to 2 lasers x 1,000W in Sapphire)

- Integrated manufacturing process: Fully integrated with Flow™ pre-print software and Assure™ quality control software

- Consistent architecture: Utilizes the same optical-train design, recoater technology, gas-flow technology, and metrology as the current Sapphire. Users can also expect similar material properties as Sapphire

- Qualified material alloys: Compatible alloys include Aluminum F357, Titanium 6AI-4V, INCONEL® 718 and HASTELLOY® X

Sapphire XC Pre-Order

Delivery of Sapphire XC will begin in Q4 2021. Early pre-order of Sapphire XC secures a price and an early manufacturing slot for the system. Existing orders of Sapphire XC will consume all available manufacturing slots for Q4 ’21 and most of Q1 ’22.

Webinar Invitation

To learn more about the value of the Sapphire XC large format system and how it addresses unmet customer needs, register for an informative online fireside chat on Oct 22nd at 10 a.m. Eastern Standard Time. Scott Dunham, Vice President of Research at Smartech Analysis will moderate a discussion with Benny Buller, founder and CEO of VELO3D. Live Q&A from the audience will be included in the webinar.

About VELO3D

VELO3D is transforming the analog supply chain to digital manufacturing. As the creator of the industry’s first SupportFree solution for 3D metal printing, their product suite is an end-to-end digital manufacturing solution for producing metal parts. With VELO3D Flow™ print preparation software, Sapphire® printer, and Assure™ quality assurance software, manufacturers can accelerate product innovation, become more agile and responsive to market needs, and reduce costs. The company is based in Silicon Valley and is privately funded. For more information, please visit https://www.velo3d.com/.

Connect with VELO3D

Twitter: https://twitter.com/VELO3DMetal

Facebook: https://www.facebook.com/Velo3Dinc/

Linkedin: https://www.linkedin.com/company/velo3d/

Media Contact for VELO3D: press@velo3d.com