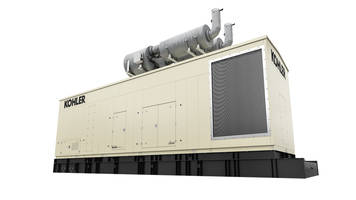

KOHLER KD Series Generators Meet Stringent Tier 4 Final Emission Standards for Non-Emergency Applications

Exhaust aftermarket system centers on selective catalytic reduction technology that offers minimal maintenance and lower ownership costs.

Kohler, Wis. (PRWeb) November 02, 2020 -- KOHLER Power Systems announces that its KD1250-4, KD2500-4, and KD3250-4 large diesel industrial generators are certified for Tier 4 EPA Final air quality standards for non-emergency applications – including prime power, peak shaving, and curtailment programs.

To control particulate matter (PM) emissions, the KOHLER K135 16-cylinder diesel engine, and K175 12- and 16-cylinder diesel engines feature superior in-cylinder emissions control technology. Developed from the ground up, the cylinder heads, combustion chamber, and high pressure common rail fuel injection system are optimized to enhance power density, decrease noise, and control emissions.

For reducing nitrogen oxide (NOx) emissions to meet Tier 4 Final requirements, Kohler has incorporated a best-in-class exhaust aftertreatment system (EATS) for the KD Series generator sets that features selective catalytic reduction (SCR) technology. Similar to on-highway engine exhaust systems, Kohler utilizes a modular approach to its SCRs – KD1250 (one SCR), KD2500 (two SCRs) and KD3250 (three SCRS). The EATS does not require a diesel particulate filter or a diesel oxidation catalyst and leverages the benefits of using SCRs in engineering and installation simplicity, lower operations costs, and minimal maintenance.

An integral component to the Tier 4 Final emission technology is the diesel exhaust fluid system (DEF), including an anti-corrosive stainless steel tank with mounted pump controls and service touchpoints that are centrally located for ease of service and maintenance. In addition, the DEF system is DC-powered by a dedicated power supply, does not require compressed air, and is purged back into the DEF tank when not in use to eliminate the possibility of DEF crystallization within the system.

All components are heated and wrapped to retain heat ensuring they will operate to expectations in all weather conditions. The SCRs share commonality of parts across the line, and also serve as critical grade silencers that are crucial in applications such as healthcare.

The exhaust aftertreatment works by injecting DEF, to derive ammonia, into the exhaust stream as it enters the SCR housing. The catalyst enhances the reaction between the ammonia and nitrogen oxides resulting in harmless byproducts of nitrogen and steam. The KD Series APM603 control unit and integrated sensors continually monitor and control all aspects of the Kohler proprietary exhaust system. This advanced controller also provides enhanced performance and monitoring features such as (+/-.25%) voltage regulation, expanded inputs and outputs, a large seven-inch color touchscreen, and the ability to parallel as many as eight generator sets.

For greater flexibility in installation across a wide range of applications, users can specify open or enclosed packaged systems (KD1250 and KD2500) from the factory that are predesigned for the EATS, which nearly eliminates application engineering requirements normally associated with aftertreatment systems in the field. The enclosures are offered in a SL2 configuration and diesel fuel tanks come standard. The DEF tank is sized to match the diesel tank and mounts within the footprint of the enclosure, all add-on items such as lights and dampers are compatible across the range, and a service box allows for DEF system control and filter access.

“We are providing the simplest yet most effective and reliable solution with lower total cost of ownership, and we’re ensuring no loss of power and performance from regeneration because there is no DPF,” said Brad Meissner, product manager for KOHLER industrial generators. “Our 3250-kilowatt generator represents the largest Tier 4 Final certified unit available in the market, and we are the only manufacturer providing a Tier 4 Final generator with a factory direct enclosed option.”

For additional details about the KOHLER KD Series, please visit http://www.KohlerPower.com.

A global force in power solutions since 1920, KOHLER manufactures complete power systems, including generators (portable, marine, residential, commercial and industrial), automatic transfer switches, switchgear, monitoring controls, and accessories for emergency, prime power and energy-management applications all around the world. The company is committed to reliable, leading edge power-generation products as well as comprehensive after-sale support.

About Kohler Co.

Founded in 1873 and headquartered in Kohler, Wis., Kohler Co. is one of America’s oldest and largest privately held companies. With more than 50 manufacturing locations worldwide, Kohler is a global leader in the manufacture of engines and power systems; kitchen and bath products; cabinetry, tile and lighting; and owner/operator of two of the world’s finest five-star hospitality and golf resort destinations in Kohler and St Andrews, Scotland. For more details, please visit http://www.Kohler.com.

Contact Information:

Todd Weber

Kohler Co.

http://www.kohler.com

920-457-4441