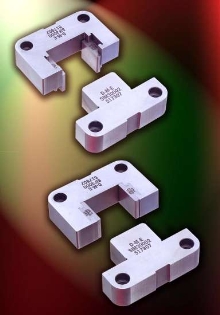

Interlocks feature interchangeable inserts.

Press Release Summary:

Providing accurate alignment of plastic mold halves, Series IN2(TM) INovative INterlocks utilize interchangeable inserts, eliminating need to replace entire side interlock set during maintenance. Graphitic steel inserts are held in place with interference-fit design that retains them when interlocks are installed on mold. There are no coatings, which could peel away under severe conditions.

Original Press Release:

New Interchangeable Inserts on IN2(TM) INnovative INterlocks Reduce Costs for Molders and Moldmakers

Replaceable wear surfaces reduce maintenance costs

April 2005 - Patented, interchangeable wear surfaces on D-M-E Company's new IN2(TM) INnovative INterlocks reduce maintenance costs for plastic molders and moldmakers alike. Interchangeable inserts eliminate the need to replace the entire side interlock set during maintenance, resulting in significant and ongoing cost savings.

The new IN2(TM) design features relatively inexpensive wear inserts of graphitic steel that are easily replaced when a mold is maintained. The inserts are held in place with a precision interference-fit design that retains them when the interlocks are installed on the mold.

Also an industry first is the material combination that has been optimized through extensive testing for this application - through-hard graphitic steel against through-hard high speed tool-steel. There are no coatings, which had been shown to peel away under severe testing conditions.

IN2 INnovative INterlocks provide accurate alignment of mold halves, are easily installed and are available in three standard sizes.

D-M-E Company, headquartered in Madison Heights, Michigan, is one of the world's largest manufacturers and distributors of mold tooling, mold components, hot runner systems, and control systems for the plastics industry. A subsidiary of Milacron Inc.,

D-M-E Company also manufactures and sells standard tooling for the die casting industry.