Composite blocks engine heat and noise.

Press Release Summary:

TUFCOTE® RM-10-75 3-layer composite works as noise barrier and heat reflector for engine-driven vehicles and equipment. It has 3/4 in. urethane foam decoupler, lead-free vinyl barrier, and top facing of aluminized, scrim-reinforced polyester. With barrier toward noise and heat source, barrier contains noise, and shiny reflective facing reduces heat transfer. Scrim reinforcement limits punctures and tears. It withstands temperatures up to 300°F.

TUFCOTE® RM-10-75 3-layer composite works as noise barrier and heat reflector for engine-driven vehicles and equipment. It has 3/4 in. urethane foam decoupler, lead-free vinyl barrier, and top facing of aluminized, scrim-reinforced polyester. With barrier toward noise and heat source, barrier contains noise, and shiny reflective facing reduces heat transfer. Scrim reinforcement limits punctures and tears. It withstands temperatures up to 300°F. Original Press Release:

Tough New Composite Blocks Engine Noise, Reflects Heat

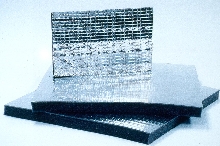

TUFCOTE® RM-10-75 composite, a new product from E-A-R Specialty Composites, is engineered to perform both as a noise barrier and heat reflector for engine-driven vehicles and equipment, from buses and boats, to generators and pumps. The three-layer composite comprises a three-quarter-inch urethane foam decoupler, a 1 pound-per-square-foot flexible lead-free vinyl barrier and a top facing of aluminized, scrim-reinforced polyester. Applied with the barrier toward the noise and heat source, the decoupled barrier effectively contains the noise, and the shiny reflective facing reduces heat transfer. The scrim reinforcement helps "ruggedize" the composite and limits punctures and tears.

New TUFCOTE RM-10-75 composite is designed to withstand demanding temperatures of up to 300°F. The three layers are fused during the manufacturing process and effectively resist the delamination that is common with adhesive layering. The polyester film facing protects against exposure to dirt, grease and fluids. The composite meets MVSS 302 flame standards.

E-A-R Specialty Composites is a leading manufacturer of high performance materials that control noise, vibration, shock and motion. Additional information is available from E-A-R by phoning toll-free (877) 327-4332 or faxing (317) 692-3111. The company's Website is located at www.earsc.com, and the e-mail address is solutions@earsc.com.