CombiTac’s Modular Connectors with MULTILAM Technology Integrate Solutions & Improve Workplace Safety

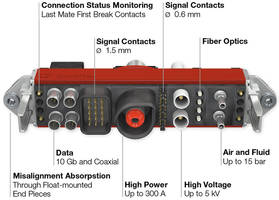

For over 20 years, the CombiTac modular connector system from Stäubli Electrical Connectors has been a great success. As a modular and freely configurable connector system, CombiTac modular connectors can meet a full range of customer requirements. Its compact, space-saving design combined with its extreme reliability make the CombiTac modular connector capable of standing up in even the harshest environments.

The primary contributor of CombiTac’s success is Stäubli’s extensive market experience with its proven MULTILAM contact technology. Through a strong dedication to innovation, Stäubli is constantly evolving its solutions to accommodate customer demands for efficiency, simplicity, and more.

“As a core feature of our products, our MULTILAM contact band provides us with tremendous flexibility in how we solve customers’ challenges,” says Adam Skare, Field Sales Engineer, Modular Connector Systems. “Whether someone needs to mate a connector a million times in regular conditions or only once in harsh conditions, we can provide different variants of our MULTILAM technology to adapt the solution to almost any customer’s needs.”

Regardless of which configuration and model range a customer chooses, CombiTac connector systems come with pre-assembled modules. Additionally, customers can order a completely customized CombiTac solution that can be fully equipped, tested for their particular application, and delivered.

Get To Know Stäubli Electrical Connectors

-

Stäubli offers the latest generation of CombiTac modular connectors that use MULTILAM technology for manual and automatic connecting with up to 100,000 cycles.

-

Their new user-friendly, tool-free click-and-connect system allows you to assemble your modular connector systems in the simplest and most time-saving way.

-

The quality and long service life of CombiTac modular connectors combined with MULTILAM technology helps ensure high productivity and lower maintenance costs with maximum operator safety.

Thomas Insights (TI): How does Stäubli Electrical Connectors stand apart from the competition?

David Marak, Head of Sales - Modular (DM): Stäubli has been around for over 125 years. It was originally founded as a textile manufacturer but has grown into a global provider of robotics, textiles, and electrical and fluid connectors. That being said, we have a long history of innovation and forward-thinking. We rely on past accomplishments and testing to keep ourselves ahead of the pack.

One of the core features of our products is the MULTILAM, which allows the contact to maintain a safer and lower temperature. It’s something that Stäubli invented, and it’s the secret sauce of our products.

Adam Skare (AS): What we do is provide integrated connector solutions for the most challenging applications in the world. We provide connectors for applications ranging from mapping out the human heart to solutions for national defense or fusion reactors. We have a strong standard product portfolio with tens of thousands of products, but where we really shine is when customers bring us a challenge that requires a custom solution.

We have special capabilities in being able to solve client problems that can’t otherwise be solved. The reason for that is our MULTILAM technology, which provides a consistent, reliable connection point for applications large and small. From heart mapping to mobile robotic platforms, the MULTILAM provides that constant connection between pin and socket that is critical to the performance of these parts.

Beyond that, you can look at mating cycles. We have customers who plug something in one time and never touch it again. We have other customers that need millions of mating cycles. We can tailor our MULTILAM band to accommodate either of these situations.

TI: What might be some of the typical questions that your customers may have for you, and how might you respond to them?

AS: It all boils down to one theme: how do you do it? How is it possible that you can do this? Some of the things that we do defy what a test engineer or production engineer would think is possible. Because a lot of them have never seen MULTILAM or seen different versions of it, they didn’t know that we’d have the ability to extrapolate the technology for their application. There have been several situations where we’ve been able to integrate solutions that customers just didn’t think were possible.

Another question we answer is how does the MULTILAM work? What does it do? What are the variations of it? What are its features, benefits, and constraints? Explaining the technology can be difficult because most people don’t know it exists. Sometimes, they don’t even know they had a problem until they’ve seen the solution. We spend a lot of time educating customers on the technical aspects and helping them choose and/or engineer a solution for their specific needs.

Adam Skare (AS): What we do is provide integrated connector solutions for the most challenging applications in the world. We provide connectors for applications ranging from mapping out the human heart to solutions for national defense or fusion reactors. We have a strong standard product portfolio with tens of thousands of products, but where we really shine is when customers bring us a challenge that requires a custom solution.

We have special capabilities in being able to solve client problems that can’t otherwise be solved. The reason for that is our MULTILAM technology, which provides a consistent, reliable connection point for applications large and small. From heart mapping to mobile robotic platforms, the MULTILAM provides that constant connection between pin and socket that is critical to the performance of these parts.

Beyond that, you can look at mating cycles. We have customers who plug something in one time and never touch it again. We have other customers that need millions of mating cycles. We can tailor our MULTILAM band to accommodate either of these situations.

TI: What might be some of the typical questions that your customers may have for you, and how might you respond to them?

AS: It all boils down to one theme: how do you do it? How is it possible that you can do this? Some of the things that we do defy what a test engineer or production engineer would think is possible. Because a lot of them have never seen MULTILAM or seen different versions of it, they didn’t know that we’d have the ability to extrapolate the technology for their application. There have been several situations where we’ve been able to integrate solutions that customers just didn’t think were possible.

Another question we answer is how does the MULTILAM work? What does it do? What are the variations of it? What are its features, benefits, and constraints? Explaining the technology can be difficult because most people don’t know it exists. Sometimes, they don’t even know they had a problem until they’ve seen the solution. We spend a lot of time educating customers on the technical aspects and helping them choose and/or engineer a solution for their specific needs.

Adam Skare (AS): What we do is provide integrated connector solutions for the most challenging applications in the world. We provide connectors for applications ranging from mapping out the human heart to solutions for national defense or fusion reactors. We have a strong standard product portfolio with tens of thousands of products, but where we really shine is when customers bring us a challenge that requires a custom solution.

We have special capabilities in being able to solve client problems that can’t otherwise be solved. The reason for that is our MULTILAM technology, which provides a consistent, reliable connection point for applications large and small. From heart mapping to mobile robotic platforms, the MULTILAM provides that constant connection between pin and socket that is critical to the performance of these parts.

Beyond that, you can look at mating cycles. We have customers who plug something in one time and never touch it again. We have other customers that need millions of mating cycles. We can tailor our MULTILAM band to accommodate either of these situations.

TI: What might be some of the typical questions that your customers may have for you, and how might you respond to them?

AS: It all boils down to one theme: how do you do it? How is it possible that you can do this? Some of the things that we do defy what a test engineer or production engineer would think is possible. Because a lot of them have never seen MULTILAM or seen different versions of it, they didn’t know that we’d have the ability to extrapolate the technology for their application. There have been several situations where we’ve been able to integrate solutions that customers just didn’t think were possible.

Another question we answer is how does the MULTILAM work? What does it do? What are the variations of it? What are its features, benefits, and constraints? Explaining the technology can be difficult because most people don’t know it exists. Sometimes, they don’t even know they had a problem until they’ve seen the solution. We spend a lot of time educating customers on the technical aspects and helping them choose and/or engineer a solution for their specific needs.