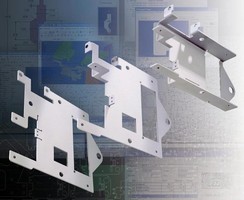

CAD Software simplifies programming of formed parts.

Press Release Summary:

CADMAN-B 3D v6.0 incorporates Smart® Technology, which assists user in finding best solution for bending process and integrates offline virtual bending with real-time bending operations. Based on work order of parts, Smart Technology imports 3D file, unfolds, generates bending sequence, and integrates parts directly to CADMAN-P/L for punching or laser cutting. Smart® Batch Processing provides ability to process batch of parts in one operation.

Original Press Release:

Strippit/lvd Releases New Version of Cadman®-b 3D Programming Software for Bending Applications

Akron, NY- Smart, Intuitive and Productive is how you could describe Strippit/LVD's latest version of CADMAN® offline programming software for CNC press brakes. The recently released version 6.0 of CADMAN-B 3D provides numerous features and enhancements for bending applications, providing more powerful capabilities in an easy-to-use software package.

CADMAN-B 3D version 6.0 introduces new Smart® Technology which assists the user in finding the best solution for the bending process and seamlessly integrates offline "Virtual Bending" with real-time bending operations.

Smart® Batch Processing provides the ability to process a batch of parts in one operation. Based on a "Work Order" of parts, Smart technology automatically imports a 3D file, unfolds, generates bending sequence and integrates the parts directly to CADMAN-P/L for punching or laser cutting.

The software's new Project Tree database driven object-oriented system allows users to approach development and virtual engineering using a structured top-down methodology. This feature displays the 3D design and bending simulation, complete part design and production parameters in one concise user interface.

CADMAN's Intuitive Automatic Tool Pre-selection technology automatically pre-selects the best tools for the job based upon material type, thickness and part geometry. This technology allows users to truly automate tool pre-selection, further reducing setup and production times.

Customizable toolbars and folders permits users to configure toolbars and folders to the working style most suited to their experience and skill level.

The latest release of CADMAN B-3D incorporates numerous other features to shorten lead times, eliminate scrap and economically manufacture small batches. Version 6.0 also provides complete flexibility for installation as a Client server, offering greater flexibility when integrated into an existing IT system.

CADMAN® is an integrated, PC-based CAD/CAM system that operates on a Windows® platform. CADMAN's automatic functions simplify programming and increase the productivity and flexibility of the sheet metal fabrication process, while its complete integration provides a total fabricating solution with a single CAD/CAM tool.

CADMAN-B 3D simplifies the programming of formed parts and automatically determines the bend sequence, automatic gauging and tool selection, all optimized for minimum tool stations and part turns. The software provides accurate and detailed profile drawings, 3D visualization and automatically communicates directly with the press brake control.

Strippit/LVD is a leading worldwide manufacturer of a comprehensive range of sheet metal/plate working machine tools and software solutions, including laser cutting systems, punch presses, press brakes, shears and automated flexible manufacturing systems. All products are integrated and supported by Strippit/LVD's CADMAN® programming package, a PC-based, Windows® compatible software solution for punching, laser cutting and bending applications.

For more information, contact Strippit, Inc., 12975 Clarence Center Road, Akron, NY 14001, call toll free 1-800-828-1527, or visit www.lvdgroup.com.