CAD-based Measuring Software supports offline programming.

Share:

Press Release Summary:

Calypso® v4.4 incorporates VAST® navigator, which optimizes measurement process and permits measurements on malleable parts such as sheet metal or plastic. It selects optimum scanning speed for each feature, and bucking mechanism function permits precise inspection of small feature transitions. Graphic-supported functions facilitate measuring process, and system directly scans different geometries one after another as total continuous line.

Original Press Release:

Carl Zeiss Delivers New Application-Oriented Functions with Calypso Software Version 4.4

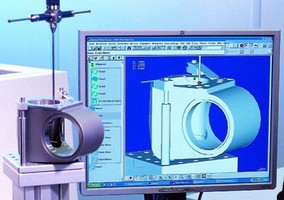

MAPLE GROVE, Sep 6 - Carl Zeiss Industrial Measuring Technology (IMT) today introduced at IMTS '06 (Booth # D-4501) Calypso® 4.4, a new version of the CAD-based measuring software.

In Calypso 4.4, VAST® navigator offers several new functions that optimize the measurement process and permit measurements on malleable parts such as sheet metal or plastic. Furthermore, additional graphic-supported functions make measuring easier and more reliable.

A key advantage for the user: VAST navigator selects the optimum scanning speed for each feature depending on the stylus geometry and the specified tolerances. The speed is very high with a rough tolerance and rigid stylus; just high enough with a narrower tolerance to ensure that the tolerance is not exceeded. Operators can be sure that scanning is always performed at an optimum speed and always with sufficient safety reserves.

The "bucking mechanism" function permits precise inspection of small feature transitions such as geometries on valve seats. Different geometries are scanned directly one after another as a total continuous line. With these very small dimensions, the acquisition of an extremely high number of measuring points available over the entire geometry, delivers reliable measuring results of the single geometry features and their further links, e.g. to points of intersection. Contours that could otherwise only be manually evaluated can now be measured automatically, because the measuring base increases with the "bucking mechanism".

Measurement of sheet metal parts

Stretched sheet metal can be deformed when set-up for measurements. This is referred to as the so-called bounce. During a measurement, the stylus moves from the edge points to empty space. The values specified in the CAD model cannot be (reliably) inspected for their actual values. The "relative measurement" function makes it possible to reliably measure the desired position by referencing locations that can be probed.

Fast measurement of car body parts permits specifying a coordinate system for new features. This enables users to very quickly determine the size and position of bores in sheet metal on this selected local coordinate system. Existing coordinate systems can be selected or redefined at any time. This fulfills fundamental requirements for measurements on metal and plastic parts.

Offline programming

CAD-based programming was optimized to make offline generation of measuring programs even easier. The workpiece does not need to exist at the time of programming. Functions such as "optimal zoom" and "rotate", as well as the visualization of local feature systems now improve this process. In particular, handling large CAD models has been optimized. Kinematic models of coordinate measuring machines have been integrated into Calypso to simulate the measuring run. The entire configuration of your hardware can be visualized. What the user sees during programming is what happens later on the real coordinate measuring machine. The time required to start the measuring run on the measuring machine is reduced considerably.

Headquartered in Oberkochen, Germany, Carl Zeiss Industrielle Messtechnik GmbH is a member of the Carl Zeiss Group. It is the global leader in CNC coordinate measuring machines and complete, multi-dimensional metrology solutions for a wide variety of industrial sectors. Approximately 1300 employees at three manufacturing locations and more than 100 sales and service centers serve customers around the world.

Carl Zeiss is a globally leading international group of companies in the optical and opto-electronic industry. In fiscal year 2004/05 the global workforce of approximately 11,500 employees generated revenue of more than EUR 2.2 billion. Further information is available at www.zeiss.com/imt and www.zeiss.com.