Bin Monitor checks rotation of paddles.

Press Release Summary:

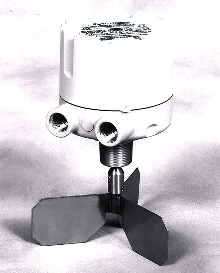

SafePoint(TM) fail-safe rotary paddle monitor detects material presence and operational status, and automatically shuts off motor when paddle is impeded. Rotation of unit's shaft is monitored by magnetized rotating disk, eliminating problems that can occur with optical systems. Unit has material sense and fail-safe outputs, twist on/off cover, local status indicating light located on top, and 2 conduit entrances for wiring access.

Original Press Release:

Complete Fail-Safe Operation

ELBURN, IL - Monitor Technologies' new SafePoint(TM) Fail-Safe Rotary Paddle Bin Monitor provides the ultimate in performance wherever critical continuous operation must be ensured. This state-of-the-art rotary paddle features patent-pending magnetic sensing technology and a new unique housing design making it the most reliable and technician-friendly point level sensor of its kind.

SafePoint(TM) utilizes Monitor's magnetic sensing technology to continuously detect both material presence and operational status. The rotation of the unit's shaft is monitored by the detection of a magnetized rotating disk (patent pending). Use of magnetic sensing techniques eliminates problems that can occur with the optical systems of other brands. Material sense and fail-safe outputs are provided on all models.

The unique housing design features a twist on/off cover, so there are no more bolts to drop or lose. A local status indicating light is located on the top of the unit for ordinary location models. The SafePoint(TM) unit also has two, conduit entrances for wiring access.

In addition, unlike most paddle units, the SafePoint(TM) incorporates a feature that automatically shuts off the motor when the paddle is impeded. This extends the life of the unit and minimizes maintenance. The SafePoint is also available with hazardous location approvals.