Balluff Introduces New Face Savers for Flush Mount Sensors

Press Release Summary:

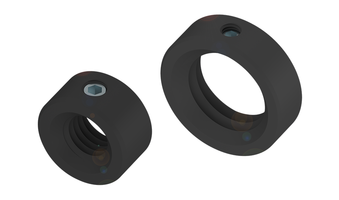

Balluff’s Face Savers are designed to protect sensors from impact damage in over travel and hostile application environments. Units come with beveled edge that allows adjustment to the placement of face saver. The face savers are designed for flush mount style inductive proximity sensors.

Original Press Release:

Balluff Offers New Way to Protect Sensor Faces from Impact Damage

Florence, KY: Balluff is excited to introduce face savers — a game-changing accessory to extend sensor life. The new-to-market face saver can be added to a flush mount sensor to increase the life of the sensor by protecting it from impact damage due to over travel and hostile application environments.

"Face Savers can almost be considered a 'Machine Up-Time Insurance Policy' for flush mount style inductive proximity sensors on the plant floor. It's a simple concept with phenomenal results," said Dave Bird, welding and stamping industry manager.

Balluff's face savers are easy to install by simply screwing the protective device on the end of the sensor housing and lining it up the with the sensor's sensing face. The beveled edge allows for adjustments to the placement of the face saver and the set screw can lock the face saver in place. Adding a face saver to a flush mount sensor can protect the sensor from impact damage and prolong its life — reducing downtime and decreasing maintenance needs.

About Balluff Inc.: Balluff Inc. is the U.S. subsidiary of Balluff GmbH, Neuhausen, Germany. Balluff is a leading supplier of networked IO-Link control system architectures that unlock the potential of the IIoT and Industry 4.0. Balluff offers a wide range of intelligent IO-Link and industrial Ethernet sensors in a variety of technologies including inductive, photoelectric, capacitive, and magnetic as well as magnetostrictive linear position sensors, magnetic tape linear encoders, industrial RFID systems, and industrial vision systems. Balluff provides cost-saving, process-enhancing solutions to machine builders and manufacturers to control, regulate, automate, assemble, position, and monitor manufacturing, assembly, and packaging sequences. Industries served include: automotive, packaging, food processing, beverages, tire, primary metals, conventional and alternative energy, semiconductor, plastics, and fluid power.