Bag Insertion Machine suits continuous-duty applications.

Share:

Press Release Summary:

PBI-II Poly Bag Insertion Machine is designed for high speed placement of poly bag liners in erected cases. It operates with other weighing, filling, case forming and closing equipment in automated or manual packaging lines. Machine can handle KD case sizes of 24, 32, and 42 in. Safety enclosure with interlocked doors protects personnel during operation. Handwheel provides height and width adjustments.

PBI-II Poly Bag Insertion Machine is designed for high speed placement of poly bag liners in erected cases. It operates with other weighing, filling, case forming and closing equipment in automated or manual packaging lines. Machine can handle KD case sizes of 24, 32, and 42 in. Safety enclosure with interlocked doors protects personnel during operation. Handwheel provides height and width adjustments. Original Press Release:

Fully Automatic PBI-II Poly Bag Insertion Machine Offered By K & R Equipment

Operates with other weighing, filling, case forming, and closing equipment in automated or manual packaging lines

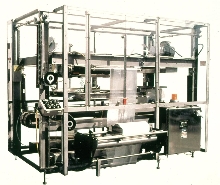

San Jose, Calif., February 4, 2002 - K&R Equipment, Inc., of San Jose, California, announces their new fully automatic PBI-II Poly Bag Insertion Machine designed for high speed placement of poly bag liners in erected cases.

This compact, ruggedly built machine is especially suited for reliable, continuous-duty bulk packing applications. It can handle KD case sizes of 24, 32, and 42 inches, with larger capacities available on special order. The machine can also accommodate totes and drums

The PBI-II receives an already erected case from a case former or hand operation. A roll-fed, preformed poly bag is automatically inserted into the case, opened, and cuffed over the extended upper case flaps. A stainless steel plate equipped with an air hose and nozzle closes down onto the upper case flaps to form a sealed chamber. A blast of air then forces the poly bag liner tightly against the interior walls of the case, free of air pockets between the bag and case. The lined case is sent on for filling and sealing.

According to Fred Krueger, president of K&R Equipment, Inc., "The new PBI-II machine is designed to provide a cost-effective way to increase the productivity of existing bulk packing facilities, as well as ease the conversion from manual and semi-automatic operations to high-tech automation."

The PBI-II features easy setup with simple handwheel height and width adjustments and can be equipped with programmable logic controller and/or special electrical equipment or devices for added automation capabilities.

A safety enclosure with interlocked doors protects personnel during operation. The machine has low power and air consumption and is available in stainless steel and coated models to meet USDA and special environmental requirements.

New web rolls can be easily spliced to expiring rolls with an optional roll positioning and heat sealing subassembly. In addition, an optional bag seal attachment system adds straight or chevron seals on the closed-end gussets of poly bag tube stock. This eliminates entrapment of semi-liquid and powdered

product in bag corners.

About K&R Equipment, Inc.

K&R manufactures and markets a new generation of bulk packing

systems, which includes their Case Erector/Poly Bag Insertion System and Poly Bag Decuffer/Package Top Sealing System designed for use with most weighing and filling machines in automated packing lines. K&R also offers a line of corrugated production equipment including Folder-Gluers, Wax Impregnating Systems, Corrugator Chiller Systems, Closed Loop Cooling Systems for single facers, and Dust Removing Systems.