Automatic Brazing Machine processes 275 parts/hour.

Press Release Summary:

With Automatic Brazing Machine, steel/stainless steel assemblies can be brazed in controlled atmosphere with filler metals such as copper. Atmosphere is created in enclosed fixture, which surrounds part during heating cycle. Induction heat source is typically used to bring filler metal to liquidus temperature. Displacing oxygen, 95 Nitrogen/5 Hydrogen blend produces clean steel parts without scaling and carbon buildup associated with open-air brazing.

Original Press Release:

New Automatic Brazing Machine Introduced

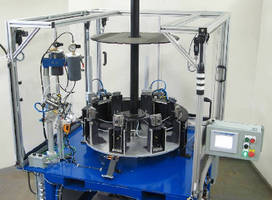

Willoughby, Ohio. Fusion is pleased to announce the availability of a new machine which permits steel/stainless steel assemblies to be brazed in a controlled atmosphere with inexpensive filler metals like copper. This atmosphere is created in an enclosed fixture, which surrounds the part during the heating cycle. Typically, an induction heat source is used to bring the filler metal to liquidus temperature.

The production sequence begins with an operator who loads assemblies into stainless steel fixtures. Deposits of Fusion Copper Paste Alloy are applied to the joint areas automatically or with a hand-held dispensing device. The fixture enclosure then mates with an external, sealed guard throughout the heating and cooling cycle. A 95Nitrogen/5Hydrogen blend displaces oxygen to produce clean steel parts without the scaling and carbon buildup normally associated with open-air brazing.

Induction atmosphere brazing is an alternative to furnace brazing, especially if part volumes are not high. Production rates up to 275 per hour are typical. For more information, contact Tony Straniero.