Automated Waste Removal System Speeds Facemask Production

WasteTech from Lundberg Tech Removes Trim Waste Without Stopping Line

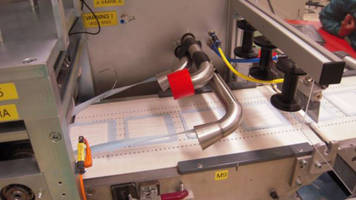

Newark, DE: The WasteTech All-In-One trim removal system from Lundberg Tech, Newark, Del. (LundbergTech.com) automatically captures the edge trim waste generated during automated facemask production, cuts it into confetti, and collects it for recycling or disposal without interrupting production. Conveniently installed next to the production line, the WasteTech All-In-One eliminates line stoppages for manual waste handling and removal and allows manufacturers to maximize the capabilities of their automated mask production lines. Unsanitary, unsightly accumulation of edge trim waste on floors or billowing over containers is also eliminated, along with the potential dust hazard.

Proven for manufacturing medical grade surgical masks, civilian facemasks, and other multi-layer, nonwoven personal protective equipment, the WasteTech vacuum waste removal system encompasses the inlet tubes, granulator with silencer, fan ventilator with silencer, air separator, cartridge dust filter, and built-in bag holder, all set within a clean, compact, attractive housing. The trim handling system is offered in five models to suit nearly any type of edge trim, label matrix, or other waste material, and meet nearly any production speed or requirement. The WasteTech All-In-One units are stocked in the company's Newark, Delaware facility and ready for delivery and quick installation.

For more information, contact Lundberg Tech, Inc., 667 Dawson Dr., STE C, Newark, DE 19713; (302) 738-2500; info@lundbergtech.com, lundbergtech.com

Media Contact: Joshua Frazier at joshua@lundbergtech.com, 302.738.2500 ext. 21 or Karsten Kejlhof at kejlhof@lundbergtech.com, +45 21219988 in Denmark