Air Amplifier doubles line pressure at point of use.

Press Release Summary:

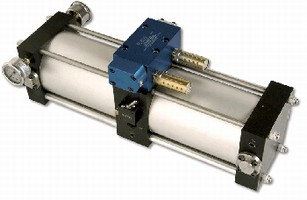

Offering flow rates up to 29 scfm, Air Amp(TM) AA-160 can achieve pneumatic pressures from 100-300 psi with 60-150 psi air drive pressure. Unit features aerospace PTFE-based dynamic seals and aircraft quality aluminum components. It is suited for demanding applications where pneumatic line pressure at point of use is inadequate or where greater force is required in air cylinder or actuator than line pressure can provide.

Original Press Release:

New Development in Air Boosters

Air Amp(TM) Doubles Line Pressure at Point of Use

Milford, Conn., July 14, 2006 - Pneumatic pressures from 100 to 300 psi with 60 to 150 psi air drive pressure can be achieved with a newly developed air driven Air Amplifier. Similar in design to the smaller model AA-54, the new larger model offers flow rates up to 29 SCFM.

Designed and built in the USA by Interface Devices, Inc. (IDI), the new Model AA-160 Air Amp incorporates robust design features such as aerospace PTFE based dynamic seals and aircraft quality aluminum components in a compact package. The company reports the Air Amp design objective was to offer increased value through a simple, robust and affordable air driven pump with significantly longer service life.

The AA-160 Air Amps are well suited for demanding applications were pneumatic line pressure at the point of use is inadequate or where greater force is required in an air cylinder or actuator than line pressure can provide. The AA-160 can also be configured to pressurize many other industrial gasses such as nitrogen or hydrogen.

Interface Devices, Inc. has been designing and manufacturing custom fluid-power components for more than 30 years. Other products include custom air driven liquid pumps, air and gas boosters, fluid to fluid boosters, zero-leak directional valves.

Additional information can be retrieved from www.interfacedevices.com or by phoning 1-800-539-0885.