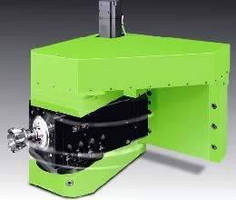

Sauter B-Axis Assembly for CNC Lathe

Utilizing SAUTER's B-Axis technology enables the complete machining of a work piece in a single clamping on a CNC Lathe which increases accuracy and reduces non-productive times

With the Y-axis and tool magazine - the ideal solution.

• Productivity is increased through the high performance turning and contour milling of complex work pieces

Compact, high performance powered spindle:

• Configured for fast, automatic tool changing (HSK or Capto)

• Exceptional loading capacity for turning operations

• Only one tool, hence outstanding clearances to avoid collisions

Zero backlash pivoting unit:

• Infinitely variable, high accuracy positioning through AC servomotor and pre-loaded gear train (pivoting angle 210°)

• Spindle position is locked with Hirth-type coupling in 5° increments

• Direct angle measuring system ensures accurate machining of the required contour

With the combination of a B-Axis Rotary Table and Disc-Type Turret, you eliminate the need for a tool magazine.

• Infinitely variable, zero backlash, high accuracy positioning with AC servomotor and pre-loaded gear train (pivoting angle 180°)

• Increased loading capacity during machining operations

• Locking system with Hirth-type coupling in 5° increments

Repetitive Precision (+/- 0.0008 mm over 100 mm radius)Â

• Disc-Type Turrets

• Head-Type Turrets

• Crown-Type Turrets