Particle Vision Instrumentation Measures Actual Image Of Individual Particles

To Reveal Their True Shape, Size And Identity

FlowCAM® Eliminates Reliance On Entrenched Methodology And Inherently Flawed Data

Patented Technology Reveals What's Under the Curve In A Histogram

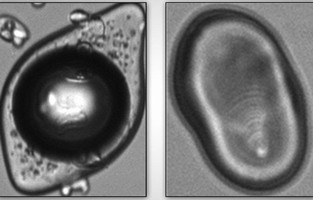

Yarmouth, ME: What's under the curve in a histogram? The FlowCAM® particle vision instrumentation from Fluid Imaging Technologies, Yarmouth, Maine (www.FluidImaging.com), reveals the answer to the question that has confounded quality control managers and other particle analysis professionals for years. The automated FlowCAM takes high resolution, full color digital images of particles and cells with dramatic clarity to permit the shape and size of each particle to be precisely measured based on its actual shape and size as imaged rather than based on the assumption that all particles must be spherical, as required by the traditional instrumentation that lacks the vital imaging capability.

While such outmoded particle analyzers compel lab managers, research scientists, process engineers, QA/QC officers, water engineers and other professionals to base conclusions on the equivalent spherical diameter (ESD) measurement and its inherently flawed assumption of sphericity, the FlowCAM provides dozens of measurement parameters based on the actual particle image itself including shape, size, area, perimeter and elongation, yielding the accurate, statistically significant data that permits highly informed analysis and decision-making.

Further, the high speed imaging FlowCAM includes proprietary pattern recognition and image management technology that automatically characterize and identify each particle in real time to visually and mathematically reveal and document different particle types in a heterogeneous sample even if the different particles share the same ESD. Prior to the development of the FlowCAM, particle analyzers assumed such particles were of the same type and often yielded misleading data.

For more information, contact Lew Brown, Fluid Imaging Technologies, Inc.; 65 Forest Falls Drive, Yarmouth, ME 04096; 207.846.6100.; Fax 207.846.6110; fluidimaging.com; lew@fluidimaging.com.

This encapsulated flavor (left) and potato starch (right) are measured and characterized by the FlowCAM® particle vision and analysis system based on their actual images. This eliminates reliance on the equivalent spherical diameter (ESD) measurement, which would conclude erroneously that the encapsulated flavor particle and potato starch cell are the same type and size.

Media Contact:

Paul Entin at 908.479.4231; paul@eprmarketing.com or Lew Brown at 207.846.6100; lew@fluidimaging.com