Dematic Corp.

Grand Rapids, MI 49505

Software Automation System targets grocery retailers.

With advanced load cubing algorithms, Dematic IQ™ 2.1 helps maximize number of cases on pallets and roll containers. Advanced multi-criteria optimization works to eliminate product damage and load instability. Dematic iQ 2.1 also optimizes efficiency of split-case picking for small items like health and beauty products. Software incorporates advanced goods-to-person picking strategies using...

Read More »Crossbelt Sorter offers non-contact data communications.

Suited for distribution and warehouse operations, FlexSort SC3 provides precise positive sorting of poly bags, pieces, stuffed envelopes, cartons, and totes using discrete belt conveyors mounted on carriers in re-circulating loop configuration. Drive system can be configured with linear induction drive motors or with linear synchronous motors. For power and data transmission, sorter can be...

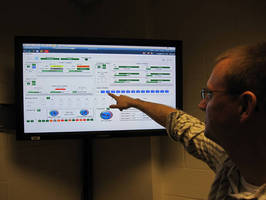

Read More »Warehouse Information Software supports smart phones, tablets.

Enabling remote management, Mobile Monitor lets users monitor and control warehouse and distribution operations from smart phone or tablet. Remote access to real-time information via Wi-Fi connection helps keep facility operations running at optimal levels. Regarding warehouse areas from receiving to shipping, interactive dashboards provide insight into KPIs, area progress, and labor statistics....

Read More »Dematic and Crown Equipment Alliance Launches Lasertrucks+(TM) Solution

GRAND RAPIDS, MI --- Dematic, a leading supplier of logistics systems for the factory, warehouse, and distribution center, and Crown Equipment Corporation, one of the world's leading forklift manufacturers, today announce an alliance to collaborate on the research and development of new products that improve warehouse and distribution center productivity. The two companies are proud to introduce...

Read More »

Dematic Introduces Suite of Modernization Solutions

Upgrade programs for material handling systems, facilities, & operations Grand Rapids, Mich. (March 23, 2010) -Dematic Corp., supplier of logistics systems for the factory, warehouse and distribution center, has introduced a suite of modernization products and services designed to increase productivity and reduce operating costs. The offering includes a wide variety of solutions arranged in three...

Read More »

Multi-Belt Sorter handles packages weighing up to 75 lb.

Designed to handle and sort packages ranging from 6-36 in. in length, MB100 offers rates exceeding 100 packages/min, enhancing pre-sorting, value add, kitting, pre-shipping, and shipping activities. Sorter is suited for automated transport of small products in wide range of industries such as parcel (small and flat), media (CDs, DVDs, books), food and beverage, wine and spirits, e-commerce,...

Read More »HK Systems Selected To Provide Automated Library System For Australian University

MILWAUKEE, WISCONSIN, MARCH 16, 2009 --- HK Systems, Inc., North America's leading automated material handling and supply chain software total solutions provider, today announces being selected by Macquarie University, Sydney, Australia, to provide an Automated Library System for their new state-of-the-art library. Currently under construction, the new library is the first Australian university...

Read More »Modular Conveyor System optimizes carton control.

Featuring scalable design, Rapistan Modular Conveyor System can be configured with motorized rollers, standard ac drives, or variable frequency drives. Carton control is optimized through segmented belt conveying surface with automatic tracking and self-tensioning belts. Mounted onboard, controls are connected with CAN Bus, allowing parameters such as conveyor speed, accumulation mode, and sleep...

Read More »Automated Storage and Retrieval Staging System is scalable.

Featuring multiple levels of AS/RS rack structure, carrier vehicles, buffer conveyors and software, Multishuttle provides product sequencing. Each level of rack structure includes input/output conveyor and carrier vehicle that travels horizontally to access loads stored in rack structure. Extraction device on each carrier vehicle accesses loads in rack. Load sequencing occurs as loads are...

Read More »Dematic Partners with Dot Foods on Fully Automated Warehouse

Innovative Technology to Power Future Strategy for Frozen Food Products Atlanta, Georgia – December 17, 2019 - Dematic announced today it will partner with Dot Foods, the largest food industry redistributor in North America, on Dot Food’s first fully-automated warehouse. The new 117,000 square-foot facility will be a key strategic asset for Dot Food’s frozen food distribution, providing new...

Read More »Dematic Announces Strategic Partnership with Opex

GRAND RAPIDS, MICHIGAN, September 9, 2019 — Dematic today announces a partnership agreement with OPEX Corporation that enables Dematic to act as an integrator of Sure Sort™, a small-item sorting system. The agreement expands the omnichannel order fulfillment offering of Dematic and provides customers with more options that bring productivity and efficiency to item order consolidation. As a...

Read More »Dematic Names Bernard Biolchini EVP and CEO, Dematic Americas

GRAND RAPIDS, MICHIGAN, July 22, 2019 — Dematic’s Bernard Biolchini has recently been appointed EVP and CEO for the Americas Region, covering the company’s operations in Canada, the United States and Mexico. Biolchini joined the company in 2014 and previously held the position of Managing Director, Dematic Southern Europe. Hasan Dandashly, President and CEO of Dematic stated, “Bernard...

Read More »Dematic Selected as âWorld Trader of the Yearâ

Company’s Commitment to the Global Marketplace Along with Its Strong Presence in West Michigan Recognized at Annual WMWTA Ceremony GRAND RAPIDS, MICHIGAN, May 7, 2019 — Dematic was recently honored by the West Michigan World Trade Association (WMWTA) as its World Trader of the Year. The company was honored at this year’s event ceremony, held May 1 in Grand Rapids, Michigan. WMWTA is an...

Read More »Dematic to Establish Global Headquarters in Midtown Atlanta Tech Hub

City’s rise as a tech powerhouse creates perfect fit for world leader in supply chain technology and innovation Atlanta – April 10, 2019 — Dematic recently announced it will establish its global headquarters in Atlanta, securing approximately 40,000 square feet of space in the Coda complex in Midtown’s Tech Square. The move will add an estimated 230 additional jobs as the company grows...

Read More »Dematic to Automate Material Flow for Plastics Manufacturer

Atlanta, Georgia – February 7, 2019 — Dematic, a leading global supplier of integrated automated technology, software and services to optimize the supply chain, has been selected by a plastics manufacturing company to design and implement an Automated Guided Vehicle System (AGVS) for intra-plant delivery of materials. The manufacturer specializes in plastic injection molding and produces...

Read More »Dematic to Implement Automated Buffer System for Meat Processor

ATLANTA, GA – November 16, 2018 – Dematic, a leading global supplier of integrated automated technology, software and services to optimize the supply chain, announces plans to implement an automated meat buffering and storage solution in a meat processing facility for Australian Lamb Company. The new Dematic system will be used to buffer meat products in a chilled and frozen environment and...

Read More »Dematic to Implement Robotic Order Fulfillment Solution for Grocery Retailer

ATLANTA, GA – October 30, 2018 – Dematic, a leading global supplier of integrated automated technology, software and services to optimize the supply chain, announces plans to implement a robotic order fulfillment system for Drakes Supermarkets, an independent grocery retailer based in Australia. The new robotic system will be used to piece pick inventory items for retail store replenishment...

Read More »Dematic White Paper Provides Update on Mobile Automation

ATLANTA, GEORGIA – October 16, 2018 – Dematic, a leading global supplier of integrated automated technology, software and services to optimize the supply chain, has released a new white paper that provides a technology update regarding Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs). The white paper, Automated Guided Vehicles (AGVs) vs. Autonomous Mobile Robots (AMRs):...

Read More »Dematic to Open New Sequencing and Distribution Center in North Texas

GRAND RAPIDS, MICHIGAN – September 26, 2018 – Dematic, a leading global supplier of integrated automated technology, software and services to optimize the supply chain, today announces it will open a new sequencing and distribution center to accommodate growing customer demand for automated technology solutions. The new sequencing and distribution center will replace an existing smaller...

Read More »