Mini Diaphragm Chuck suits micro machining applications.

Share:

Press Release Summary:

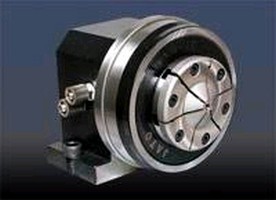

Comprised of diaphragm chuck, chuck actuator, and spindle unit, Model JAM100 can achieve total TIR under 0.001 mm. It is most suitable for machining fiber connectors, micro bearings, optical components, medical coronary stents, and spindles of micro motors, hard disks, and CD/DVD players. Chuck can also be customized to user requirements, including higher speed and tailor-made jaw pads.

Original Press Release:

JATO JAM100 Mini Diaphragm Chuck with Spindle Unit Now Released for Micro Machining Applications

Taichung, Taiwan, Nov. 29, 2006 - JATO Precision, the professional designer and manufacturer of diaphragm chucks and cylinders/collet closers, is proud to present its JAM100 Mini Diaphragm Chuck with Spindle Unit to the market. JAM100 is specially designed for micro machining or micro manufacturing applications. With built-in air cylinder and spindle unit, the total TIR can be under 0.001mm.

JAM100 comprises of a diaphragm chuck, a chuck actuator, and a precise spindle. With these 3 elements combined together, all the factors that may influence the chucking accuracy are largely eliminated. JAM100 also has a compact size. It's only as big as your fist. And with its mini size, JAM100 is your ideal choice for designing special machines that require extremely high chucking accuracy.

Although general machining still occupies a large portion of today's manufacturing applications, the importance of micro machining (micro manufacturing) has become notable. To meet with this market trend, JAM100 was therefore developed. What's best is JATO can customize JAM100 according to clients' requirements, such as higher speed and tailor-made jaw pads. JAM100 is most suitable for machining fiber connectors, micro bearings, optical components, medical coronary stents, and spindles of micro motors, hard disks, and CD/DVD players.

To learn more about JAM100 Mini Diaphragm Chuck with Spindle Unit or JATO Precision, please visit www.jato-precision.com/submicrochuck.htm or contact JATO via email: info@jato-precision.com.

About JATO Precision

In 1981, JATO Precision Industries Incorporation started out as a designer and manufacturer of hydraulic and pneumatic chucks. With the mission to provide tailor-made products, JATO Precision has fulfilled customers' needs with its high accuracy chucks for the past two decades.

In recent years, JATO's chucking technology has taken a leap from conventional chucks to micro meter ones. With greater accuracy, faster speed, and more delicate clamping force, JATO's super precision products take chucking operations to a higher level, making accuracy-critical applications and fragile part-clamping tasks possible.

Along the way, JATO's unique designs have been patented in many countries, including Germany, United States, and Japan. And yet, JATO Precision didn't stop here. JATO keeps striving for introducing better products into this market. Super precision, easy installation, and manageable cost are what we promise to offer.