Mine-Duty Belt Cleaner lessens tensioning, installation concerns.

Press Release Summary:

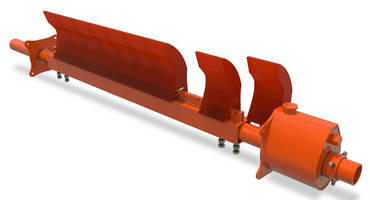

Designed for 20–84 in. dia pulleys servicing belts with widths 24 in. and up, Mine Duty Exterra Primary Belt Cleaner solves problems related to constant tensioning maintenance and difficult installation in tight areas. Set For Life (SFL) technology maintains constant, accurate tension during life of blade, and 3-piece pole facilitates management during installation. By being segmented into 6 in. chunks, scraper blade can contour against blade for even wear on wide belts.

Original Press Release:

Superior Unveils New Mine Duty Exterra® Primary Cleaner at MINExpo International 2016

Morris, Minn. – Superior Industries Inc., a U.S. based manufacturer and global supplier of bulk material processing and handling systems, is expanding its line of Exterra Belt Cleaners with a new mine duty model. Designed for better performance on larger pulley assemblies, the Mine Duty Exterra Primary Belt Cleaner debuted at MINExpo International 2016.

According to the manufacturer, the Mine Duty Exterra Primary Belt Cleaner solves pain points related to constant tensioning maintenance and difficult installation in tight areas.

Superior's belt tensioner features patent pending Set For Life (SFL) technology that maintains constant, accurate tension during the life of the blade. Operators set the tension during installation and never have to adjust it again. Versus an oversized, difficult to install, one piece pole, the Mine Duty Exterra Primary Belt Cleaner's three piece pole is lighter and easier to manage during installation, especially in tight, hard-to-get-to chute systems.

Additionally, the scraper blade is segmented into 6" chunks, allowing it to contour against the blade. This allows for a more even wear on wide belts typically used in heavier, mine duty applications.

The Mine Duty Exterra Primary Belt Cleaner is designed for pulleys larger than 20" diameter up to 84" diameter, servicing belts with widths 24" and up.

About Superior Industries, Inc.

Superior Industries engineers and manufactures groundbreaking, bulk material handling equipment and cutting-edge components. From its headquarters in Morris, Minnesota, USA, the manufacturing firm supplies bulk crushing, screening, washing and conveying systems for industries including construction aggregates, mining, bulk terminals, agriculture, power and biomass. In addition to its home plant in Minnesota, the 43-year-old Superior operates from additional engineering and manufacturing plants in Alberta, Canada; Arizona, USA; Georgia, USA; Michigan, USA; Nebraska, USA; and New Brunswick, Canada.

For more information, contact:

Corey Poppe, Marketing Communication Manager

315 East State Highway 28

Morris, Minnesota 56267 U.S.A.

+1 (320) 589-2406

corey.poppe@superior-ind.com

http://www.superior-ind.com/

http://www.facebook.com/superiorindustries