Machine Monitoring System delivers decision-making intelligence.

Press Release Summary:

Able to continuously monitor machines for changes in vibration, pressure, and machine speed, WATCHMAN Online Systems™ provides actionable data for strategic decision-making about maintenance and capital expenditure spending as well as production performance optimization. Server-based data collection and reporting tool, used by manufacturing plants for operation-critical assets, includes hardware with wired and wireless applications as well as battery-powered and line-powered options.

Original Press Release:

Azima DLI Launches WATCHMAN Online Systems Update

New Options Streamline Infrastructure and Improve Testing Capabilities

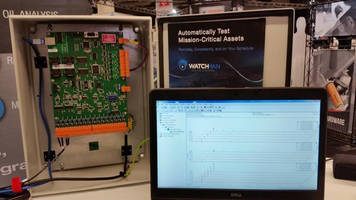

WOBURN, Mass. — Azima DLI, the global leader in condition monitoring for industrial machinery, announced today the release of a new version of WATCHMAN Online Systems™, the server-based data collection and reporting tool used by manufacturing plants worldwide for operation-critical assets. WATCHMAN Online Systems can continuously monitor machines for changes in vibration, pressure, and machine speed to provide executives, technical experts, and maintenance and reliability managers with actionable data for strategic decision-making about maintenance and capital expenditure spending as well as production performance optimization.

This release of WATCHMAN Online Systems includes new data collection hardware with wired and wireless applications as well as battery-powered and line-powered options. The traditional use of major communication cabling is now replaced by taking advantage of existing networked LAN lines, making installation faster and easier while reducing the startup costs for deployment.

According to Michael DeMaria, Azima DLI director of product management, “Decreasing the footprint of our condition monitoring systems saves our customers money and improves diagnostic testing for remote or hazardous locations —it’s a win-win for both the executives in charge of budgets and the safety of those who work around the equipment. We want our customers to succeed, and every improvement we make is focused on adding value to their investment.”

WATCHMAN Online Systems convert raw data into actionable information, dramatically reducing the time that plant engineers and vibration analysts spend on identifying machine problems reducing downtime and increasing productivity. Leading companies in industries ranging from aerospace to metals processing to pharmaceuticals all rely on WATCHMAN Online Systems to maintain their rotating machinery.

The updated WATCHMAN Online Systems also contain the new version of ALERT Online Engine™ 3.0, the software that configures customized testing parameters for each monitored machine. In addition to support of new data types, this software significantly improves communication between multiple hardware acquisition devices and the centrally-hosted diagnostic software.

The WATCHMAN Online System is being installed and commissioned in May by China-based BKC Technology Company across multiple power facilities in their predictive maintenance programs. BKC director of international cooperation, Wang Xiaoshi, is pleased with the new WATCHMAN Online Systems. “We look forward to supporting our valued customers with this advanced technology from Azima DLI. As we partner together, we expect to fulfill our joint goal of improving the efficiency of condition-based monitoring and maintenance of industrial operations throughout China.”

In addition to the traditional vibration measurements acquired from permanently installed accelerometers, velocity probes or eddy current probes, WATCHMAN Online Systems can also acquire process measurements via DC voltage input and 4-20mA current loop sensors. WATCHMAN Online Systems can also be integrated with portable data collection programs.

About Azima DLI

Azima DLI serves the global manufacturing industry by offering best-of-breed condition monitoring systems, data-driven diagnostics, and proactive analysis for plant equipment. The company’s monitoring programs are tailored to the demands of each plant, from simple data collection to full-scale assessment and reporting for C-level staff and engineers. For more information, call +1-781-938-0707 or visit www.AzimaDLI.com.

About Beijing BKC Technology CO., LTD.

Beijing BKC Technology CO.,LTD. is a professional equipment maintenance management solution provider in China. As a certified national high-tech enterprise and a responsible public company, BKC is dedicating on delivering the most advanced technology of equipment monitoring, inspection, maintenance and management to industrial plants in China. BKC is headquartered in Beijing, with offices across China. For more information, call 86-010-62818088 or visit www.BKCtech.com

Copyright © 2015 Azima Holdings, Inc. All Rights Reserved.

All other brand names, product names, or trademarks belong to their respective holders.

Media Contact:

Laura Alikpala

PR for Azima DLI

Phone 206.842-7656 x 1035