Depalletizer provides container stability.

Press Release Summary:

Model 108 has heavy steel C channel frame incorporating over 1600 lbs of counterweight within twin elevator towers for vibration-free operation. Layer elevator drive shaft utilizes 3 1/2 in. dia torque tube design for stability. Elevator table, which is guided with 8 wide-faced roller bearings, is carried by industrial roller chain. Depalletizer runs glass, plastic, metal cans and composite containers interchangeably, without instability.

Original Press Release:

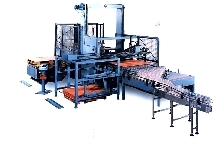

A-B-C BULK DEPALLETIZER IS ENGINEERED FOR PERFORMANCE AND RELIABLE OPERATION

Tarpon Springs, FL - A-B-C's Model 108 Bulk Depalletizer is designed for power and built for performance from the ground up, offering a host of design strengths not found on other machines. In addition, the Model 108 ensures smooth operation with exclusive features that enhance container stability, whether running plastic, glass, cans or composite containers.

Constructed with heavy steel "C" channel, the rugged depalletizer frame incorporates over 1600 pounds of counterweight contained within the twin elevator towers, to ensure smooth, accurate and vibration-free performance, even at maximum layer load. Large diameter drive shafts are utilized throughout, including the container sweep and conveying systems. The layer elevator drive shaft utilizes a unique 3-1/2" diameter torque tube design that delivers stable performance under the most demanding conditions. The elevator table, which is guided with eight wide-faced roller bearings, is carried by heavy, high strength, industrial roller chain for exceptional performance.

Exclusive features maintain container stability from pallet to discharge ensuring optimum line efficiency. Before a layer of containers is transferred from the pallet to the transfer table, layer-stabilizing mechanisms square both the transferring layer and the layer below. During layer transfer, the layer below is held securely by side mounted friction plates and the tier sheet is retained in position by four tier sheet grippers.

Additionally, the variable frequency motor drive allows a "soft start" during initial descent, ramping to higher speed, then slowing before reaching the discharge table, to eliminate the risk of jerky motions and resulting container instability. These important features are standard equipment on the Model 108 depalletizer, which runs glass, plastic, metal cans and composite containers interchangeably.