Universal Compact Cams cover diverse application range.

Press Release Summary:

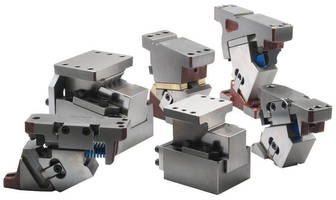

LamCam™ includes 13 series of Aerial and Die Mount Universal Cams that cover low-volume, light-duty to high-volume, heavy-duty applications. Cam widths are available from 50–600 mm, each with common footprint to other cam manufacturers. Universal Cams are offered with single or double wear plates, mechanical or nitrogen spring return, and V-guidance system ensures precision guiding. Available for piercing, flanging, and trimming operations, Cams are available from 0–75.

Original Press Release:

DaytonLamina Unveils New Universal Cam Line in FABTECH Booth#B1101

Dayton, OH – DaytonLamina will unveil their LamCam™ line of universal compact cams in booth #B1101 at FABTECH in Atlanta, November 11-13. With 13 series of Aerial and Die Mount Universal Cams, this comprehensive lineup covers all applications from low volume light duty to high volume heavy duty. Cam widths are available from 50mm to 600mm, each with common footprint to other cam manufacturers.  LamCam Universal Cams are offered with single or double wear plates for ease of maintenance, and either mechanical or nitrogen spring return. A V-guidance system ensures precision guiding. Products are available worldwide, with industry-leading deliveries. Service and support provided through DaytonLamina's extensive technical support network.

LamCam™ Universal Compact Cams are ideal for piercing, flanging and trimming operations. They are available from 0 to 75.   Additional information is available at http://www.daytonlamina.com/lamcam-universal-cams-0.

Dayton Progress is a recognized leader for manufacturing and supplying tools and accessories to the Metal Stamping and Metal Forming industries globally. Dayton's more than 800 employees ship hundreds of thousands of tools each year from its 10 factories in North America, Europe and Asia to 20,000 customers in 70 countries.

Dayton Progress Corporation is a division of Dayton Lamina™, a MISUMI Group Company.  As the world-wide leader in the manufacture of catalog and special punches, punch blanks and other precision tooling, they provide single source convenience for tooling in both standard-inch and metric sizes. In addition to nanoceramic grease, they offer a full standard line of precision punches, pilots, die buttons and retainers in configurations to suit any manufacturing requirements, as well as other custom tooling. For additional information visit them online at www.daytonprogress.com, or e-mail them at info info@daytonprogress.com or call (937) 859-5111. Write to Dayton Progress, 500 Progress Road, PO Box 39, Dayton, OH 45449-0039.