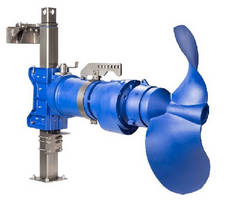

Impeller / Propeller / Turbine - Agitators / Mixers

Submersible Mixer targets biogas production applications.

Share:

Press Release Summary:

Serving as back-up mixer, scum breaker, or flow accelerator in biogas production and wastewater treatment, Amaprop 1000 features nodular cast iron propeller and 2 mechanical seals in tandem arrangement that seal off gearing and motor compartment. Oil reservoir between seals is filled with environmentally friendly oil that keeps seal faces lubricated and cool. Utilizing helical spur gears, mixer is powered by 3-phase 10–20 kW motor with maintenance-free bearings and temperature sensors.

Original Press Release:

New Mixer for Biogas Plants

At EuroTier in Hanover, from 13 to 16 November 2012, Frankenthal-based KSB Aktiengesellschaft presented a new kind of low-speed submersible mixer for use in biogas production and waste water treatment. The new Amaprop 1000 can serve as a back-up mixer, scum breaker or flow accelerator. It can be used alone or in combination with larger mixers and agitators.

The new mixer for use in biogas production has a hard-wearing propeller made of robust nodular cast iron designed for years of reliable service. Its contours were developed with the aid of computational fluid dynamic (CFD) simulations. It can generate high volumetric flow rates, producing a maximum axial bulk flow.

Two mechanical seals in tandem arrangement reliably seal off the gearing and motor compartment. An oil reservoir between the two mechanical seals is filled with environmentally friendly oil that keeps the seal faces lubricated and cool. A leakage chamber between the oil chamber and the gear unit provides additional safety. A sensor is optionally available for monitoring the leakage chamber. The cable entry is absolutely water-tight, and a plug connector in the motor space connects the cable to the motor winding, hence facilitating in-situ replacement of the cable.

Robust, quiet-running, long-life helical spur gears are used, and the three-phase motors occupy a rating range of 10 to 20 kW. The motors are series-equipped with maintenance-free bearings and temperature sensors – plus a moisture sensor - to protect the windings against overheating and ingress of moisture. The windings are designed to cope well with operating temperatures up to 60 °C in thermophilic systems without overheating.

A stainless-steel lowering device makes it possible to adjust the mixer's mounting angle and height easily.