Solid Carbide Drills are offered in non-coolant thru versions.

Press Release Summary:

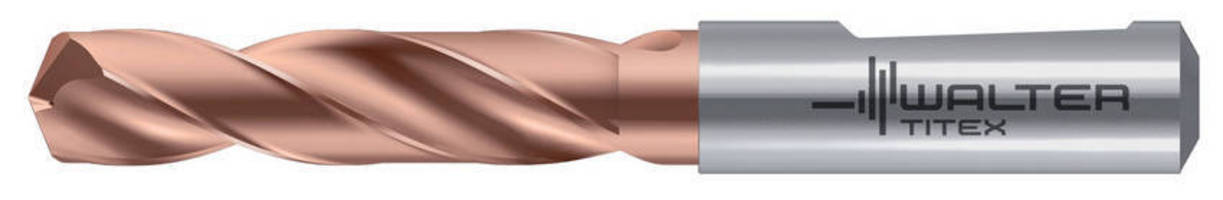

Non-coolant thru versions of Titex X-treme(TM) solid carbide high-performance drills are available from 1/8-¾ in. dia and can be used with all common materials. Featuring 4-margins design that promotes stability relative to workpiece, drills maintain position at point of entrance or exit as well as when machining inclined surfaces. Additional features include aluminum chromium nitride-based XPL coating, 140° point angle, and cylindrical shank or whistle-notch shank.

Original Press Release:

Walter USA, LLC Expands Walter Titex Solid Carbide Drill Line

High-performance drills from Walter now available in non coolant thru versions.

Waukesha, WI - Walter Titex X-treme(TM) solid carbide high-performance drills from Walter, currently in use in a wide variety of industries including automotive, energy, die and mold and general metalworking applications are now available as non-coolant thru drills.

Like the popular internally-cooled series, these non coolant thru X-treme drills are available from 1/8" to ¾" (3 to 25 mm) diameter and can be used with all common materials. Like the internally cooled line, these new Walter Titex X-treme drills feature a four-margins design which improves the stability of the drills relative to the workpiece. This enables the drills to maintain position at the point of entrance or exit, and also when machining inclined surfaces.

This improvement in drill stability boosts both process reliability and productivity, even in critical drilling situations. That's because in many cases the processing time for components is reduced, as the user is able to forgo prep operations such as milling a flat surface or drilling pilot holes. The four margins also ensure an improved hole surface finish.

All drills in the Walter Titex X-treme solid carbide series boast an advanced aluminum chromium nitride-based XPL coating. In addition to the universal use of the tools for all ISO material groups, the tools also deliver enhanced tool life. Other features of this range of products include a 140 degree point angle and a cylindrical shank or whistle-notch shank according to DIN 6535. The h6 shank tolerance is suitable for shrink fit chucks.

These new solid carbide high-performance drills cover the same application areas as the Alpha® 2 series but provide increased performance and tool life.

Walter USA, LLC offers an extensive line up of cutting tools for milling, drilling, turning, boring and specialized tooling for unique applications through its competence brands Walter Valenite, Walter Titex and Walter Prototyp. As well as multi-level service programs through its Walter Multiply brand. Headquartered in Waukesha, Wisconsin the company has a strong network of distributors and field engineers across North America. The Walter name is synonymous with productivity, thanks to more than 80 years of developing cutting tools and inserts that set new standards in production. Walter USA, LLC combines over 75 years of U.S.-based tooling production with long-standing traditions of quality and innovation.