Sheet Molding Compound features specific gravity of 1.2.

Share:

Press Release Summary:

Offering weight savings without degradation of mechanical properties, Tough Class A Ultra Lite® uses treated glass bubbles to replace some CaCO3, allowing resin to adhere to matrix and increase interfacial strength between bubble and resin. Technology results in resin mix that makes molded parts resistant to handling damage, and prevents micro-cracks that cause paint pops, pits, and blistering. Treated bubbles also help with paint adhesion and bonding characteristics.

Original Press Release:

Continental Structural Plastics Introduces TCA® Ultra Lite® OEM-Approved, Patented Technology Offers Industry-Leading Performance

Auburn Hills, Michigan — Continental Structural Plastics (CSP), the global leader in lightweight composite solutions, today introduced its Tough Class A (TCA) Ultra Lite, a 1.2 specific gravity (SPg) SMC formulation that provides engineers the ability to design with a lower specific gravity material without sacrificing mechanical properties, surface qualities and adhesion requirements. This material is already approved by major automotive OEMs and is programmed for a production vehicle beginning in January 2015.

Depending on the body component being developed, design studies have shown that CSP Ultra Lite offers a weight savings of up to 21 percent over the company’s mid-density TCA Lite® (1.6 SPg), and 35 percent over its industry-proven standard TCA material (1.9 SPg). CSP’s complete line up of TCA materials offers OEMs an array of weight-savings options to meet their most demanding design challenges.

“We have developed a patented technology that enables us to achieve superior weight savings without experiencing any degradation of mechanical properties,” explains CSP Chairman and CEO Frank Macher. “TCA Ultra Lite is an affordable alternative to aluminum, and offers engineers all of the advantages that come with using SMC instead of metal in body design. The fact that we are seeing no degradation of mechanical properties means lighter parts do not have to be made thicker, or incorporate structural reinforcements, to maintain the desired performance qualities.”

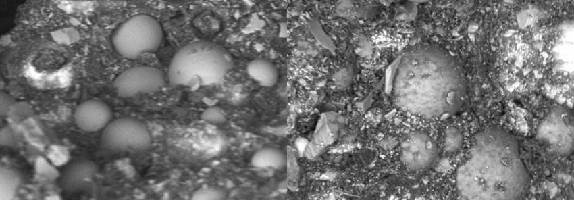

Specifically, Ultra Lite technology uses treated glass bubbles to replace some of the CaCO3, allowing the resin to adhere to the matrix and increase the interfacial strength between the bubble and the resin. This is a patented treatment technology that results in a more robust resin mix that makes molded parts more resistant to handling damage, and prevents the micro-cracks that cause paint pops, pits and blistering. The treated bubbles also help with paint adhesion and bonding characteristics. When combined with CSP’s patented vacuum and bonding manufacturing processes, the result is a material with a premium Class A finish with paint and gloss qualities comparable to metals, including aluminum.

About Continental Structural Plastics

Continental Structural Plastics is the world’s largest SMC compounder and manufacturer. For more than 40 years, CSP has provided leading-edge technologies in lightweight materials and composite solutions for the automotive, heavy truck, HVAC and construction industries. Headquartered in Auburn Hills, Michigan, CSP provides full-service engineering support, and holds more than 50 active patents covering materials development and manufacturing processes in composite materials formulation, design and manufacturing technologies. For more information, visit www.cspplastics.com.