Rail Guided Crane suits high-speed picking applications.

Press Release Summary:

Acting as storage/retrieval unit for moving items, rail guided stacker crane system helps companies improve productivity, inventory control, and floor space usage while also reducing worker fatigue. Density and rate of operation can replace conventional static rack or carousels to optimize vertical storage space. Effective in forward pick operations, crane also suits applications that include buffering and storage of raw materials, work-in-process, and finished goods.

Original Press Release:

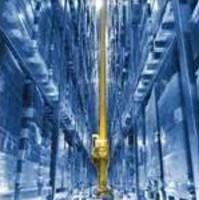

Diamond Phoenix Announces New Rail Guided Stacker Crane

New Rail Guided Stacker Crane from Diamond Phoenix

Lewiston, Maine - Diamond Phoenix has announced their new rail guided stacker crane system. This new system is a high-speed storage/retrieval (S/R) unit that moves items swiftly and accurately to support high-volume picking operations. The system is designed to help companies reduce overhead costs while improving productivity, inventory control, worker fatigue and floor space usage.

Effective in forward pick operations, the rail guided stacker crane is well suited for applications that include the buffering and storage of raw materials, work-in-process and/or finished goods. The fast, high-density can replace conventional static rack or carousels to maximize vertical storage space within a minimal footprint.

Diamond Phoenix is an industry leader, providing expert design and integration, advanced software systems and a complete suite of material handling technologies. Diamond Phoenix is headquartered in Lewiston, Maine with regional offices in Atlanta, GA, Philadelphia, PA, Charlotte, NC, Grand Rapids, MI, Los Angeles, CA, Cincinnati, OH, Denver, CO and London, England. Visit www.diamondphoenix.com