Micro-Machining Service targets medical device market.

Share:

Press Release Summary:

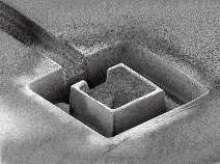

Offering sub-micron tolerances, UV Laser Micro-Machining Service processes polymers and plastics, ceramics, glass, metals, semiconductor materials, diamond and precious metals at 355, 351, 308, 266, 248, 193, and 157 nm wavelengths. Laser systems are equipped with air bearing motion stages to ensure precision and accuracy. Typical applications include micro-fluidics, sensors, nozzles, micro-screens, particle traps, MEMS, MOEMS, micro-dicing, biosensors, and micro-vias.

Original Press Release:

JPSA Laser Announces UV Laser Micro-machining for Medical Device Manufacturing

Hollis, New Hampshire, USA - J P Sercel Associates (JPSA Laser) offers precision UV laser micromachining services - with micron-scale features and sub-micron tolerances - for a variety of medical device manufacturing applications. Typical applications include micro-fluidics, sensors, nozzles, micro-screens, particle traps, MEMS, MOEMS, micro-dicing, biosensors (lab-on-a-chip), micro-vias, photo-ablation, photo-machining, micromachining of plastics, ceramics, hard dielectrics, glass and metals, non-destructive high-resolution marking, micro-lithography to 1 micron resolution, high speed drilling, selective material ablation, doping, annealing and more. Materials processed include polymers and plastics, ceramics, glass materials, metals, semiconductor materials, diamond and precious metals, and others. JPSA Laser's core capabilities include expertise in UV materials processing at 355nm, 351nm, 308nm, 266nm, 248nm, 193nm, and 157nm wavelengths.

JPSA Laser's contract manufacturing facility houses state-of-the-art UV excimer and DPSS laser workstations. The applications laboratory is also equipped with a host of diagnostic equipment for laser process development and characterization. JPSA engineers have developed F2 laser, optics, calorimetry, and beam delivery technology, allowing JPSA to offer comprehensive testing of VUV optics and materials processing services at 157nm. Most of the JPSA laser systems are equipped with state of the art air bearing motion stages to ensure high precision and accuracy.

JPSA Laser's core capabilities include expertise in UV materials processing at 355nm, 351nm, 308nm, 266nm, 248nm, 193nm, and 157nm wavelengths; a fully equipped applications development laboratory staffed with Ph.D. laser scientists; JPSA's contract manufacturing facility is ready to meet customer needs from prototype to high volume production.

JPSA products and services include UV excimer and DPSS laser micro machining systems, UV and VUV laser beam delivery systems, UV laser materials processing development, optical damage testing, and excimer laser refurbishment services. For more information, visit www.jpsalaser.com, or contact the company at 17D Clinton Drive, Hollis, NH 03049 USA, Tel. 603.595.7048, fax 603.598.3835.