Laser Cutting Systems provide cutting speeds to 1,181 ipm.

Press Release Summary:

Comprising 3 models, TLH Series features fiber optic beam delivery with 2, 3, and 4 kW power options. Five-axis, 3D fiber laser processing machines provide X, Y, and Z axis travel up to 177, 45, and 20 in., respectively, with positioning and cutting accuracy of 0.0015 in./19.68 in. With controllable optical head angles of +720° on C axis and rotation of +135° on A axis, systems are suitable for cutting thin gage mild steel, aluminum, or stainless steel, and work best with materials less than 3/8 in.

Original Press Release:

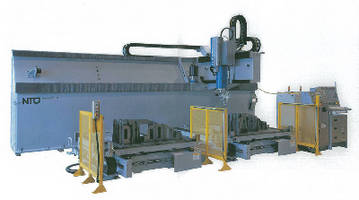

NTC America Introduces New Ultra High Speed Laser Cutting System

New TLH Series 5-axis laser cutting system offers high cutting speeds and versatility

NTC America—Laser Group, Novi, MI, has introduced its fastest performing system yet with the TLH Series 5-axis, three dimensional IPG Fiber Laser processing machine. The TLH Series, of which there are three models, provides cutting speed to 1,181 in/min (30,000mm/min)and features fiber optic beam delivery with 2, 3 and 4 kW power options.

The series is ideal for hot stamping operations and has shown itself to be more accurate than other operations such as robotic delivery. Further, the series is ideal for any production application that requires high speed cutting of thin gage mild steel, aluminum or stainless steel…working best with materials less than 3/8” thick. These highly rigid machines allow operator access from the opening of one side of the machine for optimal accessibility. The feature provides dramatically superior operability and workability.

The series provides X, Y and Z axis travel up to 177 in. (4500mm), 45 in. (1150mm) and 20 in. (500mm) respectively with positioning and cutting accuracy 0.0015”/19.68” (0.04mm/500mm) Combined with its controllable optical head angles of +720° on the C axis and rotation of +135°, on the A axis, the TLH can operate in virtually all cutting applications.

The series can be modified with two integral pallet changers or a large indexing table (up to 114 in.) for increased flexibility and production. The system uses a Windows® operating environment, non-contact gap sensor technology, controllable optical head angles, and operator friendly joystick and hand-held pendant—along with a teach mode that all help to make complex cutting simple.

The TLH Series was developed to provide, through simple programming and operation of integrated motion and laser systems, high-productivity performance in cutting complex parts, to generate intricate beam paths and to adapt laser parameters to various cutting requirements. Â

The TLH also provides precision cutting, established first on its cantilever-style construction and solid base that are the foundation of its operating accuracies. The construction features are matched with AC servo motor drives, ball screw feeds and linear ball guide mechanisms that provide movement tolerances of +0.0019 in. per 19.6 in. of travel distance (+0.05mm per 500mm). To assure consistent beam penetration despite contours and form irregularities, the TLH’s non-contact sensor provides rapid response to changes in the gap between optics and material to maintain the beam’s optimum focus.Â

The TLH Series programs can be prepared either by using the teaching playback system or by using NC data made with an optional automatic progrramming system and corrected by the teaching playback system if necessary. The teaching mode allows for settings for on/off laser beam, pulse rate, laser power, cutting speed and other settings. In addition, the control incorporates memory storage for multiple part programs and includes integral subroutines such as linear, circular and spline interpolations, copying and mirror shaping, pattern downloading, circular cutting and corner rounding from center point definition, scheduling parts and operations for unattended production.

In addtion to the TLH Series, NTC America’s lineup of laser processing machines includes the TLM Series 3-dimensional, 5 axis, the TLZ Series 2-dimensional, 3-axis systems with flying optics, the TLV Series 3-axis hybrid machines for large, wide workpieces, and the TLX Series high power, 3-axis models in cantilever and gantry configurations.

NTC America, Laser Group, 46605 Magellan Dr., Novi, MI 48377

Phone: Toll Free 800-NTCLASR • 248.560.1200 • Fax: 248.560.0215 • Online: www.ntclaser.com