Inductive Chokes operate with frequency converters.

Share:

Press Release Summary:

Available in 36–300 mm diameters, Inductive Chokes are installed at frequency converter's input, where they provide recovery, and at converter's output, where they act as filter chokes. Units feature powder composite core with low magnetostriction, and encapsulated design that ensures devices emit only low-intensity stray fields. Chokes can be produced for frequencies up to 200 kHz and currents up to 1,000 A. Depending on application, degrees of protection from IP00–IP66 are available.

Original Press Release:

Inductive Components for Industrial Applications

Milwaukee/Graben-Neudorf, Germany, - SMP Sintermetalle Prometheus GmbH Co KG (SMP) introduces at this year’s Electronica in Munich inductive components for industrial applications, for example frequency converters. The components are low-loss, have good EMC characteristics and a space-efficient design.

The inductive components are installed both at the frequency converter’s input, where they provide power recovery, and at the converter’s output, where they act as filter chokes. Because of their space-saving design and low-noise operation, SMP’s chokes are also used in frequency converters’ internal DC links, as both single and common-mode chokes.

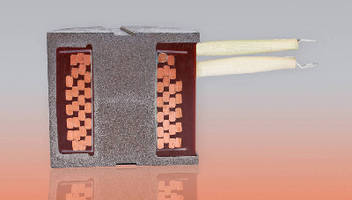

The components’ cores consist of powder composites with low magnetostriction, which SMP specifically engineers for each application. With their low eddy current and hysteresis losses, the materials contribute to the components’ exceptional efficiency. Their encapsulated design ensures that the components emit only low-intensity stray fields – another requirement in frequency converters – which allows other components to be placed in close proximity to the choke without running a risk of magnetic interaction with the choke. With their compact design, SMP’s chokes occupy 25 percent less space than conventional components.

The chokes can be produced for frequencies of up to 200 kHz and currents of up to 1000 amperes. Their sizes range from 36 mm to 300 mm diameter and their weight from 50 g to 130 kg. Depending on the application, degrees of protection from IP00 to IP66 are available. The chokes can be used in a temperature range up to 180 degrees Celsius. All components are RoHS- and REACH-compliant and the materials used are UL-listed. Beside industrial applications, SMP’s inductive components are used in wind turbines, in photovoltaic installations, in railway and medical engineering as well as in drives and power electronics.

Illustration: Sectional view of a SMP choke with a winding of high-frequency wire.

Trade shows:

SMP at Electronica 2012, 13 to 16 November 2012, Neue Messe München (New Munich Trade Fair Centre), Munich, Germany: Hall B6 Stand 153

Company information:

SMP Sintermetalle Prometheus GmbH & Co KG develops and manufactures inductive components and magnetically soft materials, cores and mouldings. Based in Graben-Neudorf near Karlsruhe, Germany, the company was founded in 1982 by Vasilios Gemenetzis and today employs 250 people. Research and development have been key aspects of the company’s philosophy ever since its foundation. SMP’s product range includes low-loss inductive custom components based on in-house-developed powder composites, such as filter, commutating, step-up converter, power recovery and single-conductor chokes. Many of its products are used in the railway industry. The market for inverters for photovoltaic systems that feed solar energy into the electricity grid and for converters for wind turbines is also experiencing strong growth. SMP has become one of the key global suppliers of magnetically soft materials for industrial applications, serving customers throughout the world.