Continuous Solvent Vapor Monitors reduce exhaust airflow.

Press Release Summary:

670 Series Continuous Solvent Vapor Monitors are placed at source of emissions. Continuous monitoring allows air recirculation in processes to reduce exhaust airflow. Incinerator has less air to process, therefore requires less fuel. Additionally, 670 Series meets safety standards set by NFPA to protect incinerator as well as employees.

670 Series Continuous Solvent Vapor Monitors are placed at source of emissions. Continuous monitoring allows air recirculation in processes to reduce exhaust airflow. Incinerator has less air to process, therefore requires less fuel. Additionally, 670 Series meets safety standards set by NFPA to protect incinerator as well as employees.Original Press Release:

Reduce VOC Disposal Costs

Reduce VOC Disposal Costs

Fairfield, NJ. Federal law requires that the exhaust streams of process ovens and dryers be run through a pollution control device to reduce VOC emissions. From printing, coating, and laminating to chemical, pharmaceutical and specialty finishers, incineration is one common way to bring exhaust emissions

in line with EPA requirements.

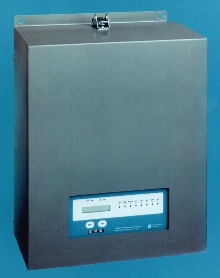

The fuel costs to operate incinerators can be reduced substantially by adding Control Instruments' Model 670 Series, continuous solvent vapor monitors, at the source of emissions. Continuous monitoring allows more air recirculation in the process, reducing the exhaust airflow. The incinerator has less air to process, therefore requiring less fuel.

Additionally the 670 Series will meet with safety standards set by the NFPA to protect the incinerator as well as employees.