Brazing/Soldering Machine is designed for small assemblies.

Press Release Summary:

Rotary Index 100 is 36 in. wide by 48 in. deep and operates at rates between 100 and 200 parts per hour, depending on assembly mass and configuration. Brass, copper, steel, stainless, and aluminum can be joined on machine. Unit is equipped with clear, acrylic guarding on 3 sides. It requires 120 VAC, natural gas or propane, 80 psi air, water and drain.

Rotary Index 100 is 36 in. wide by 48 in. deep and operates at rates between 100 and 200 parts per hour, depending on assembly mass and configuration. Brass, copper, steel, stainless, and aluminum can be joined on machine. Unit is equipped with clear, acrylic guarding on 3 sides. It requires 120 VAC, natural gas or propane, 80 psi air, water and drain.Original Press Release:

Fusion Introduces New Brazing/Soldering Machine

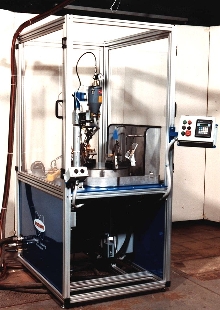

Willoughby, Ohio. Fusion is pleased to announce the availability of a new machine for brazing and soldering. The Rotary Index 100 is designed for relatively small assemblies since its footprint is only 36"W X 48"D. Rates are typically between 100 - 200 parts per hour, depending on assembly mass and configuration. Brass, copper, steel, stainless, and aluminum can all be joined on the machine.

The production sequence begins with an operator who loads the assembly into a stainless steel fixture, A deposit of Fusion Paste Filler Metal is applied to the joint area with an automatic dispenser. The assemblies then index through two or three flame heat stations and an air and water cooling sequence before unloading.

The Rotary Index 100 is equipped with clear, acrylic guarding on three sides. Utilities required are 120 VAC, natural gas or propane, 80 psi air, water, and drain.