Andor iStar Camera Keeps an Eye on Europe's ITER Star

Development of methodology for Tokamak reactor maintenance made possible by Andor iStar high speed and resolution ICCD

Belfast, UK – With the current focus on green and renewable energy sources, most of which capture the sun’s energy second-hand, it’s easy to overlook the global effort to build a fusion reactor that will replicate the process at the core of our Sun - i.e. energy production through fusion of atoms - to help meet mankind's energy needs. Due to one of the largest scientific endeavours of our time, ITER is on track to build the world’s biggest fusion device in the south of France with a projected working life of more than twenty years.

However, this fusion process will indirectly lead to the build-up of thick deposits of material layers on the reactor walls and the team at ITER need to know how fast the deposits are growing, as well as their chemical composition, so that the maintenance of the reactor can be better planned and made more efficient with minimum impact on operation time. Now, an international team using the speed and resolution of Andor’s iStar ICCD camera has published a spectroscopic method that can determine non-invasively the composition of the layers, including specific beryllium containing samples, for the first time.

“Shutting down any nuclear reactor is an expensive exercise, so a non-invasive diagnostics technique that maximises service intervals has the potential for massive savings,” says Dr Antti Hakola, senior scientist at the VTT Technical Research Centre of Finland. “Our laser-induced breakdown spectroscopy (LIBS) experiments are important as they show that the composition of the deposits as well as their thickness can be determined without taking any components out of the reactor. In addition, this is the first time that beryllium samples, which are very significant for fusion applications, have been analysed and we now know their ablation characteristics.

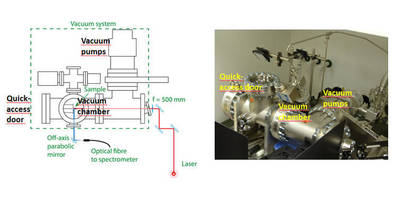

“We compared products from a number of manufacturers before choosing the Andor SR-750 spectrograph and Andor iStar 340T intensified CCD (ICCD) camera”, continues Dr Hakola. “The key for us was the very fast (nanosecond) and precise (picosecond) temporal resolution as our main criteria were to ensure fast triggering, that the width and delay of the recording gate can be flexibly changed, even to a sub-ns regime, and that the spectral resolution would be high (less than 0.05 nm). The spectrometer has proved an utterly reliable tool and the Andor software has also been helpful, particularly in obtaining kinetic series of how spectral lines evolve as the number of laser pulses increases.”

According to Antoine Varagnat, Product Specialist at Andor, “The ambition of the ITER project to prove that fusion could be a viable renewable source of energy for the future is indeed extremely exciting for the scientific community and the public. But harnessing the energy produced by the fusion of atoms is not a simple endeavour, and numerous aspects of the process have to be well understood. I am delighted that the iStar’s high-speed and ultra-sensitive resolution has allowed this international Research team to show that LIBS can be used not only as a non-invasive diagnostics technique in ITER but also in other fusion reactors being researched. This work may be lead to the development of vital tools and process in furthering the research into this technology - the ultimate green energy solution.”

To learn more about the iStar series of ICCD (intensified CCD) cameras, please visit the Andor website at http://www.andor.com/scientific-cameras/istar-iccd-camera-series.

About Andor

Andor is a global leader in the pioneering and manufacturing of high performance scientific imaging cameras, spectroscopy solutions and microscopy systems for research and OEM markets. Andor has been innovating the photonics industry for over 20 years and continues to set the standard for high performance light measuring solutions, enabling its customers to break new ground by performing light measurements previously considered impossible. Andor’s digital cameras, are allowing scientists around the world to measure light down to a single photon and capture events occurring within 1 billionth of a second.

Andor now has over 400 staff across 16 offices worldwide, distributing products to over 10,000 customers in 55 countries. Andor’s products are used in a wide range of applications including medical research to further the understanding of heart disease, cancer and neuronal diseases such as Alzheimer’s and Parkinson’s disease. Andor also has applications for forensic science and astronomy. Through continuous dialogue with customers and strong teamwork, Andor continues to innovate ground-breaking products that improve the world in which we live.

More information is available at www.andor.com.

About Oxford Instruments plc

Oxford Instruments designs, supplies and supports high-technology tools and systems with a focus on research and industrial applications. Innovation has been the driving force behind Oxford Instruments' growth and success for over 50 years, and its strategy is to effect the successful commercialisation of these ideas by bringing them to market in a timely and customer-focused fashion.

The first technology business to be spun out from Oxford University, Oxford Instruments is now a global company with over 2300 staff worldwide and is listed on the FTSE250 index of the London Stock Exchange (OXIG). Its objective is to be the leading provider of new generation tools and systems for the research and industrial sectors with a focus on nanotechnology. Its key market sectors include nano-fabrication and nano-materials. The company’s strategy is to expand the business into the life sciences arena, where nanotechnology and biotechnology intersect.

This involves the combination of core technologies in areas such as low temperature, high magnetic field and ultra high vacuum environments; Nuclear Magnetic Resonance; x-ray, electron, laser and optical based metrology; atomic force microscopy; optical imaging; advanced growth, deposition and etching.

Oxford Instruments aims to pursue responsible development and deeper understanding of our world through science and technology. Its products, expertise, and ideas address global issues such as energy, environment, security and health.

For further information, please contact Andor Technology direct or their marketing agency, Catalyst Communications.

Andor Technology plc.

Corporate Headquarters

7 Millennium Way

Springvale Business Park

Belfast BT12 7AL

+44 (0) 28 9027 0812

Andor website

press@andor.com

Catalyst Communications

The Annexe

2 Crispin Way

Farnham Common

Buckinghamshire SL2 3UE

+44 (0) 1753 648 140

john.waite@catalystpr.com

Andor contact

Victoria Gault

+44 (0) 28 9027 0812

Media contact

John Waite

+44 (0) 1753 648 140