RTP Company's Conductive Compound Meets Stringent Safety Requirements for Mining Pump

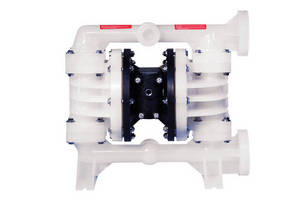

WINONA, MINNESOTA, USA - When All-Flo, a leading manufacturer of air-operated diaphragm (AOD) pumps, was challenged to construct an entire pump with conductive, but non-metallic materials, it worked in partnership with custom compounder RTP Company who recommended a material that enabled the successful production of a specialized version of the company's 1 inch (25 mm) polypropylene AOD pump.

All-Flo has been a pioneer in the use of non-metallic materials. Traditional fluid handling pump designs favored metals, but many end-users demanded non-metallic materials that better resist corrosion from harsh chemicals or reduce weight for portability. "Plastic materials provide benefits our customers need that we simply could not otherwise obtain," said Paul McGarry, All-Flo's Sales and Marketing Manager.

All-Flo's 1 inch (25 mm) pumps are the equipment of choice in mining operations because of their complete non-metallic construction. "Miners have to carry equipment down in tight elevators or often walk it from hole to hole; they tell us they really appreciate the weight difference our pumps deliver," said McGarry. "Using RTP Company's glass fiber reinforced polypropylene compounds enables us to achieve the considerable weight savings, while providing a stronger degree of resistance to atmospheric corrosion."

"While many of All-Flo's pumps can meet ATEX Directive requirements for being safe to operate in potentially explosive environments, safety standards can vary from country to country and some companies have their own safety standards that are stricter than regulations require," explained McGarry, referring to the recent customer challenge to construct a specialized version of the 1 inch (25mm) AOD pump using conductive, non-metallic materials.

"We didn't have to go far to find a solution," said McGarry. "Our engineers always say that if you need specialized materials, RTP Company is the one to talk to." Working in partnership with All-Flo and its injection molder, Royal Plastics of Mentor, OH, a number of materials were trialed and a variation of the proven RTP 100 Series glass fiber reinforced polypropylene compound that All-Flo already used was chosen after passing evaluation testing. The addition of a carbon powder provided the conductive properties to meet the very specific and stringent customer requirements.

"Not only did RTP Company provide a conductive material that had the properties and met the requirements, it had the same processability and worked with our existing molds," said McGarry. "For our molder, Royal Plastics, it's really just a matter of switching out materials for us to produce a specialized version of our 1 inch (25 mm) polypropylene pump."

For more information on RTP Company's conductive or custom engineered thermoplastic compounds, call 507-454-6900 or toll-free 800-433-4787, visit their web site at www.rtpcompany.com or e-mail rtp@rtpcompany.com.

About RTP Company

RTP Company, headquartered in Winona, Minn., is a global compounder of custom engineered thermoplastics. The company has 12 manufacturing plants on three continents, plus sales representatives throughout the Americas, Europe, and Asia. RTP Company's engineers develop customized thermoplastic compounds in over 60 different engineering resin systems for applications requiring color, conductive, elastomeric, flame retardant, high temperature, structural, and wear resistant properties.

Contact: Kris Jommersbach

Gemini Communications

Phone: +1 610-935-1633

krisj@geminiinc.com