New 3D Animation Illustrates Cost and Time Savings of the QUICK LOAD Liner AutoLength System

BEECHER, Ill./WINDSOR, Ontario — A new 3D animation from Bernard and Tregaskiss explains the benefits of the QUICK LOAD™ Liner AutoLength™ System, a revolutionary combination that increases throughput and lowers operating costs for MIG welding operations by minimizing quality issues caused by incorrect liner length.

The new animation is available on both the Bernard and Tregaskiss YouTube pages (www.youtube.com/TheBernardDifference and www.youtube.com/user/TregaskissWelds) with versions in English, French and Spanish.

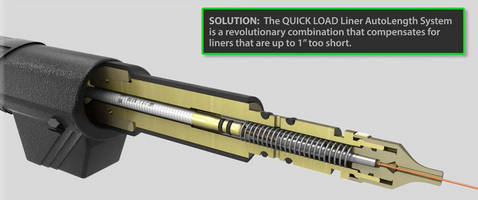

The 3D animation details how MIG gun liners that are too short contribute to weld quality issues such as premature contact tip wear, poor wire feedability, bird-nesting and burnbacks. It also illustrates how liners can often be cut too short, and the ways the QUICK LOAD Liner AutoLength System solves such issues by compensating for liners that are up to 1 inch too short.

The system operates via a spring-loaded module housed in the power pin. The AutoLength Pin partners with the QUICK LOAD Liner, which reduces liner replacement time by more than 50 percent, compared to conventional liners, by allowing welding operators to load them from the front of the gun. There is no need to remove the gun from the feeder or to cut and waste wire.

The new 3D animation explains how these innovative technologies increase the life of consumables and liners, helping viewers see the associated savings in cost and time.

About Bernard

For more information about Bernard’s welding products, visit BernardWelds.com, call 1-855-MIGWELD (1-855-644-9353), fax 1-888-946-6726, email info@bernardwelds.com or write Bernard, 449 West Corning Road, Box 667, Beecher, IL 60401. Outside North America, call +1-519-737-3030 or fax +1-708-946-6726.

Bernard, located in Beecher, Ill., manufactures premium semi-automatic GMAW (MIG) and FCAW (flux-cored) welding guns, consumables, accessories and manual arc products. For more than 60 years, Bernard has been an innovator in heavy-duty MIG welding and a contributor to improved welding productivity. Bernard is a division of Illinois Tool Works Inc. (ITW), Glenview, Ill., USA. ITW is a diversified multinational manufacturer of highly engineered components, assemblies and systems.

About Tregaskiss

For more information on welding products from Tregaskiss, call 1-855-MIGWELD (1-855-644-9353) or fax 1-877-737-2111 (in Canada and USA); write Tregaskiss, 2570 North Talbot Road, Windsor, Ontario, Canada, N0R 1L0; email info@tregaskiss.com or visit Tregaskiss.com. Outside North America, call +1-519-737-3030 or fax +1-519-737-1530.

Tregaskiss is an industry leader in the development and manufacture of robotic MIG welding guns, peripherals and consumables, and offers its products worldwide. Its product lines include TOUGH GUN™ Robotic MIG Guns and Peripherals, TOUGH LOCK™ Consumables, QUICK LOAD™ Liners, the QUICK LOAD Liner AutoLength™ System and TOUGH GARD™ Anti-Spatter Products. Tregaskiss is a division of ITW Canada Inc., a wholly owned subsidiary of Illinois Tool Works Inc. (ITW), Glenview, Ill., USA. ITW is a diversified multinational manufacturer of highly engineered components, assemblies and systems.