Industrial CT Scanning Supports Additive Manufacturing/Rapid Prototyping

Reverse Engineering in Additive Manufacturing / Rapid Prototyping

With reverse engineering applications, Industrial CT (Computed Tomography) is able to capture internal external part geometry for 3D printing, laser sintering and rapid prototyping applications. For additive manufacturing applications the dataset is typically translated to a point cloud/polygon based file in formats such as STL, WRL, TXT, PLY, and OBJ. With the point cloud file you can either go directly to printing or bring it into your CAD suite and perform modifications to the dataset prior to printing.

Note: All data is exported is only on one level as the conversion process from RAW to point cloud format, the density gray scale values are lost.

Internal Inspection in Additive Manufacturing/Rapid Prototyping

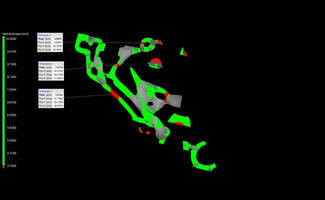

Geometry in a limited production part is occasionally required to be validated for an integral part of an assembly. By identifying wall thickness issues ahead of time in the first printed part, the design or the additive manufacturing process can be modified to ensure the limited production run is meeting the intended design parameters.

The second benefit for internal inspection is to quickly validate the part to the CAD model for internal and external deviations from the design. For customers requiring this piece of mind validation on their newly manufactured part, Industrial CT scan (CAT scan) is the only non-destructive method for validating the internal geometry in 3D to the CAD model. As a further benefit, GDT part print points and first article inspection (FAI) reports can also be generated without destroying the part.

The remaining benefit for the industry is to identify cracks, knit lines, and porosity between the intersections of resins on multi material printers. Identifying these areas ahead of time allows for adjustment to machine parameters prior to the first saleable run.