Debro Changes the Rules of the Game

A powerful new laser, massive worktable and a vision are enabling this innovative steel service center to add new levels of value for its customers.

Today, incremental improvement is no longer enough. Securing a long-term competitive advantage takes vision. That's a quality that Debro Steel, a division of Premetalco, Inc. of Brampton, Ontario, Canada manifested in abundance when it became one of the first steel service centers in North America to deploy a 7.0 kW laser. This powerful machine, a TLX-1480 three-axis laser system from NTC America-Laser Group, Novi, MI, has not only allowed Debro to cut thicker parts than ever before, and do it with precision and superior edge quality, it has also provided the foundation for dramatic improvements in the company's overall competitive position.

"This was a calculated decision on the technology," says Debro president

Gunar Zenaitis. The company had formerly relied on a four-head underwater plasma cutting system. Many of Debro's competitors, though, had advanced to newer high-definition plasma systems. "Our market is well served with hi-def plasma machines," notes Zenaitis, speaking of the heavily industrialized belt of southern Ontario from which Debro has traditionally drawn most of its customers. "So when we started looking at upgrading our cutting technology we had to ask ourselves do we want to be one of the pack with a hi-def system that's just a little bit bigger or newer, or do we want to offer state of the art, high precision cutting with a laser?"

With the TLX, Debro has clearly chosen the latter option. Designed to optimize the cutting of longer and thicker materials, these newly configured high precision 3-axis lasers are fast, powerful and more compact than traditional bridge-type laser systems with comparable work envelopes. The NTC TLX series places the laser and chiller on the system's gantry, providing for a smaller footprint and shorter beam path, which translates into space and labor savings, increased flexibility and greater cutting quality. The cantilever design and redesigned controller both allow for easier loading and unloading of parts.

The TLX Series is the fruit of NTC America-Laser Group's long experience with laser cutting challenges and opportunities. NTC is a leading manufacturer of three and five-axis laser cutting systems with a lineup that includes the TLM Series of five-axis, three-dimensional laser systems ideal for cutting complex contours and shapes; the ultra-high speed TLZ Series two-dimensional, three-axis systems with flying optics; the TLV Series three-axis hybrid machines for large configurations. Each of the models features high speed and the flexibility and accuracy to accommodate a variety of workpiece configurations and sizes.

When Zenaitis joined the company in 2006, he was given a mandate to revitalize the business. A laser purchase was already being actively considered when he came onboard; however, it was a 6.0 kW laser system with a conventional cutting table. Zenaitis and his team opted instead for a game changing 7.0 kW laser with a massive 14 by 80 ft cutting table, along with modifications to the building in order to house the new table.

"The large table was a key part of our vision for this new system," reports Zenaitis. "It opens the door for efficient processing of very large parts and, because of our ability to stage jobs, the faster processing of small parts. This versatility added with reduced part costs adds value for the customers and enhances their competitive position."

Training and support for a leap into the unknown can be a daunting prospect, but not in this case. Debro negotiated a complete turnkey-style installation, including training, with NTC distributor Paramount Machinery of Mississauga, Ontario. "NTC, Paramount, and our staff worked very hard and very well together in order to get this done so that we could quickly begin to accept our first commercial orders," explains Zenaitis. "Setting up the cutting library and conditions was done prior to any actual work being performed, and there have been no issues from the standpoint of support."

He notes that the investment has also sent a good message to Debro's employees. "By showing that we were prepared to reinvest in the company in tough times it demonstrated that we were in this for the long haul. This was a positive message, and both the challenges and the opportunities presented by the laser have been enthusiastically embraced by our people."

New economy, new approach

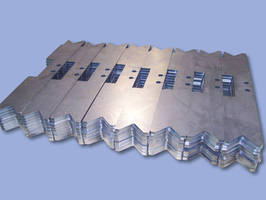

This new production system has enabled Debro to provide new services and court new customers. "In the crane industry, for instance, where the long boom would normally be constructed from several parts using multiple weldments, we can now provide them with a laser-cut 30-foot part saving them both time and money," notes Zenaitis, citing one example among many. "Similarly, the expansive new table facilitates the production of long-run small parts, increasing our productivity and reducing the cost per part." The addition of a conveyor system, which Debro installed to help automate the laser's production of smaller parts, further reduces costs for both Debro and its customers.

"This machine is producing a product that is significantly better than anything on the market ... especially when compared to plasma or oxyfuel cutting," observes Debro's general sales manager David Vachon. "The parts the laser is now producing require less work after being cut. This means that we can produce a finished part rather than a semi finished part."

Zenaitis adds that "Creating added value like this through the elimination of redundant machining, welding, handling, and transportation results in a lower total cost for our customers. Improving our customers' competitive position is the secret to our long-term success, which means better margins and better profitability for all of our supply partners." Zenaitis says that creating value in this way is more important today than ever before.

"Our customers are really challenging us to create the complex parts that they need and do so in a cost-effective manner," he continues. "Since the installation we are seeing new orders and finding new customers that are interested in the long, laser-cut parts that we can produce."

In the future Debro is looking to add forming capability to its value-added mix and to continue automating parts handling, thus increasing the laser's beam-on time, boosting productivity and further reducing the cost per part. "We have to be perceived as the best value for the money," says Zenaitis. "That's the goal we set for ourselves, and we are reaching it."

For additional information regarding NTC America and its laser products, visit www.ntclaser.com