Franklin Miller Inc.

Livingston, NJ 07039-1604

Dimminutor-® Channel Disintegrator

The Dimminutor-® Turbo model provides effective, automatic screening and grinding of wastewater solids in straight through channels and wet wells. This powerful unit reduces plastics, wood, rags and other solids to fine bits, enhancing plant operation and improving the reliability of pumps and other downstream equipment. The Dimminutor employs a smooth, continuously rotating design with high...

Read More »

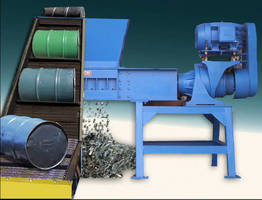

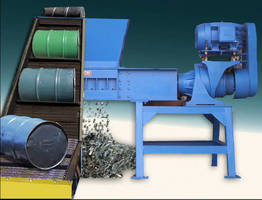

TASKMASTER-®TM2800-Shreds Steel Drums to Crumbs

The TASKMASTER TM2800 Shredder quickly shreds steel drums down to strips of metal for a major reduction in space. It also facilitates the recovery of the steel and/or the contents of the drums. These units provide fast and efficient destruction of a wide variety of bulk solids, quickly reducing bulk volume by up to 80%. With its powerful shredding action, this low speed, high torque shredder...

Read More »

In-Line Disintegrator Reduces Tough Solids

The Super Shredder-® in-line disintegrator easily reduces tough solids directly in sludge or raw sewage lines. The unit combines unsurpassed grinding capabilities with streamlined, easy to maintain features. Its innovative design provides a high level of open area to fluid flow making the Super Shredder ideal for applications requiring a heavy duty size reduction processor that can handle high...

Read More »

Channel Grinders employ 2 counter-rotating shafts.

Employing 3 or 5 hp motor and cycloidal gear drive, TASKMASTER TITAN is available with 14 x 12 to 14 x 60 in. inlet cutting chamber for handling flow rates up to 8 mgd. System employs 2 counter-rotating shafts; one cutter stack intermeshes with second one, which has larger diameter. For higher flow and wider channel applications, TASKMASTER TITAN DUPLEX models have 31 in. by up to 60 in. high...

Read More »

Granulator processes rubber without significant heat rise.

VULCANATORÃ-® reduces whole bales of synthetic or natural rubber into small bits without significant heat rise, minimizing dissolving or processing time. It includes cutting mechanism that cuts material fine enough to pass through perforated sizing screen. Built for heavy-duty operation, unit features open design and incorporates access doors that simplify maintenance. It is available in...

Read More »

In-Line Grinders handle sewage and sludge solids.

TASKMASTER TM8500 series in-line grinders reduce sewage and sludge solids to fine particles directly in pipeline systems, featuring 2 counter-rotating stacks that intermesh at close clearance to shear and shred solids into fine bits. Cutter Cartridge Technology and drop-in housing allow for removal of cutting mechanism for periodic maintenance. Supplied for open channel or in-line applications,...

Read More »

Inline Processor reduces solids to eliminate blockages.

Suitable for wet, dry, pressure, or gravity systems, PIPELINE DELUMPERÃ-® in-line processor crushes, disperses, and suspends tough solids in fully enclosed pipe systems. Fluid tight pressure rated unit has full throughput capacity of pipe to which it is connected and works stream to free flow and prevent damage to pumps and other equipment. Fabricated in carbon and stainless steel, processor...

Read More »

Bag Dump System incorporates delumper processor.

Designed to facilitate manual opening of small- to medium-sized bags without creating dusty environment, DELUMPER BAGSTATION unloads, de-agglomerates, and freshens lumpy bagged solids while introducing them into production process. DELUMPER crusher reduces lumps and agglomerates to free flowing state with positive, one pass crushing action. Along with air filtration system, options include...

Read More »

Granulator reduces size of rubber bales.

Model KM30 has low friction cutting design that reduces whole bales of natural and synthetic rubber to small bits. This 150 hp unit features large throat and split clam shell design that allows for maintenance of cutters and screens. Design minimizes heat rise so no cooling systems is needed. Optional features include automatic controller, infeed and discharge conveying system, pneumatic...

Read More »

Fine Screen employs European step bar technology.

ScreenMasterÃ-® ST, constructed of stainless steel, comes in various widths, heights, and screen openings to promote optimal degree of solids separation to meet application requirements. As solids accumulate into mat on screen, level sensor is activated, and unit is energized. Motor reciprocates bars, incrementally moving material up bar screen steps. When they reach top, solids fall off into...

Read More »

Super Shredder SS2400

The SUPER SHREDDER® in-line disintegrator reduces a variety of liquid borne solids with a unique, low headloss design. This unit features heavy duty construction and effective operation in such tough applications as tar sands and dredging as well as sewage and sludge waste and process lines. This unit reduces clogging and downtime resulting in tremendous plant savings and a fast payback of...

Read More »Increasing Wipes Use Presents a Strain On Wastewater Systems

As the Coronavirus pandemic is upending life across the country, it is also putting a major strain on the nation’s wastewater systems. Shoppers are flocking to stores to stock up on toilet paper, paper towels, tissues, and cleaning wipes as they self-isolate at home and try to keep the virus at bay. Many are flushing these items rather than disposing of them properly, which can be catastrophic...

Read More »Franklin Miller Honored for 100th Anniversary

July 11, 2018 - Franklin Miller Inc. was honored by the Township of Livingston in a ceremony commemorating the 100th anniversary of the company’s founding. The ceremony took place on July 3, 2018 at the company’s Livingston, New Jersey facility. William Galanty, President of Franklin Miller and Jake Galanty, General Manager were presented with a proclamation by Edward Meinhardt, mayor of...

Read More »Franklin Miller Unveils Expanded Manufacturing

July 13, 2016 - Franklin Miller Inc. was proud to unveil the grand opening of their 11,000 sq ft. addition to their Liviston, New Jersey manufacturing facility at a ribbon cutting celebration on July 12, 2016. This addition includes new offices, a test facility, and a high bay manufacturing area. Franklin Miller manufactures size reduction and screening equipment for environmental and industrial...

Read More »

Dimminutor-® Channel Disintegrator

The Dimminutor-® Turbo model provides effective, automatic screening and grinding of wastewater solids in straight through channels and wet wells. This powerful unit reduces plastics, wood, rags and other solids to fine bits, enhancing plant operation and improving the reliability of pumps and other downstream equipment. The Dimminutor employs a smooth, continuously rotating design with high...

Read More »

TASKMASTER-®TM2800-Shreds Steel Drums to Crumbs

The TASKMASTER TM2800 Shredder quickly shreds steel drums down to strips of metal for a major reduction in space. It also facilitates the recovery of the steel and/or the contents of the drums. These units provide fast and efficient destruction of a wide variety of bulk solids, quickly reducing bulk volume by up to 80%. With its powerful shredding action, this low speed, high torque shredder...

Read More »

In-Line Disintegrator Reduces Tough Solids

The Super Shredder-® in-line disintegrator easily reduces tough solids directly in sludge or raw sewage lines. The unit combines unsurpassed grinding capabilities with streamlined, easy to maintain features. Its innovative design provides a high level of open area to fluid flow making the Super Shredder ideal for applications requiring a heavy duty size reduction processor that can handle high...

Read More »Franklin Miller, Inc. Launches New Website

Franklin Miller, Inc., a major manufacturer of size reduction processors, has launched a new and improved website. With its updated design, clear structure and user-friendly navigation, the website provides comprehensive information about the company's quality line of DelumperÃ-® series crushers, TaskmasterÃ-® series grinders and shredders and wastewater treatment systems. The new site is...

Read More »Grinders and Screens

The new Franklin Miller CD-ROM is a comprehensive guide to the company's innovative line of wastewater grinding and screening equipment. These products offer proven solutions for removing and reducing solids in open channel, in-line or gravity installations. Profiles include the TASKMASTER Ã-® Twin Shaft Grinder, SUPER SHREDDERÃ-® In-line Disintegrator, DIMMINUTORÃ-® Channel Grinder,...

Read More »

Channel Grinders employ 2 counter-rotating shafts.

Employing 3 or 5 hp motor and cycloidal gear drive, TASKMASTER TITAN is available with 14 x 12 to 14 x 60 in. inlet cutting chamber for handling flow rates up to 8 mgd. System employs 2 counter-rotating shafts; one cutter stack intermeshes with second one, which has larger diameter. For higher flow and wider channel applications, TASKMASTER TITAN DUPLEX models have 31 in. by up to 60 in. high...

Read More »