Fusion, Inc.

Willoughby, OH 44094-4630

Brazing Alloy Paste joins copper and brass parts.

Fusion #1131 contains Blockade(TM) filler metal, consisting of atomized copper, phosphorous, tin, and silicon. Copper/copper, copper/brass, and brass/brass parts can be joined with alloy when using gas/air, gas/oxygen, or induction heat methods. Paste, with liquidus temperature of 1247Ã-

Read More »

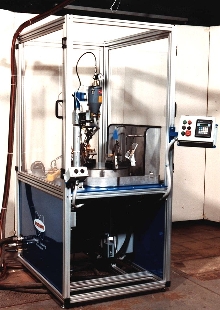

Brazing/Soldering Machine is designed for small assemblies.

Rotary Index 100 is 36 in. wide by 48 in. deep and operates at rates between 100 and 200 parts per hour, depending on assembly mass and configuration. Brass, copper, steel, stainless, and aluminum can be joined on machine. Unit is equipped with clear, acrylic guarding on 3 sides. It requires 120 VAC, natural gas or propane, 80 psi air, water and drain.

Read More »

Brazing Alloy Paste joins copper and brass parts.

Fusion #1131 contains Blockade(TM) filler metal, consisting of atomized copper, phosphorous, tin, and silicon. Copper/copper, copper/brass, and brass/brass parts can be joined with alloy when using gas/air, gas/oxygen, or induction heat methods. Paste, with liquidus temperature of 1247Ã-

Read More »

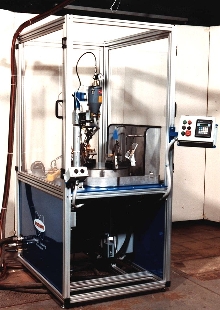

Brazing/Soldering Machine is designed for small assemblies.

Rotary Index 100 is 36 in. wide by 48 in. deep and operates at rates between 100 and 200 parts per hour, depending on assembly mass and configuration. Brass, copper, steel, stainless, and aluminum can be joined on machine. Unit is equipped with clear, acrylic guarding on 3 sides. It requires 120 VAC, natural gas or propane, 80 psi air, water and drain.

Read More »