Parkinson Technologies Announces Technology Improvements to Surface Winding Product Line

Company's PositranÃ-® Transfer System Improved for Faster Performance, Higher Reliability; Allows Fully Automatic Roll Changes at Line Speeds Woonsocket, RI (January 28, 2009) . . . Parkinson Technologies has announced it has made numerous technology improvements to its line of Surface Winding Systems that will provide users with improved performance and reliability. Parkinson Surface Winding...

Read More »Surface Winders can roll materials in diameters up to 60 in.

PAC 50 winders feature compact hydraulic system that uses high-speed digital electronics for lay-on pressure control, which reduces blocking at core. They also feature device to bring new core up to speed prior to transfer as well as integrated, motorized shaft hoist system. Touchscreen controls are mounted on pendant and systems include ac digital drives and center assist drives. Shafts are...

Read More »Dual-Turret Winder meets Blown Film Industry needs.

With compact design able to handle 24, 30, or 40 in. dia rolls on 3 and 6 in. cores, Dual Turret Winders have frame design constructed of 1 3/8 in. thick steel side plates - stress relieved and normalized - tied together with 5 girths measuring 6 x 8 in. Products are offered with 44-124 in. wide roll face and offer Taper Tension control via PLC touch-screen. Indexing gear design limits turret...

Read More »

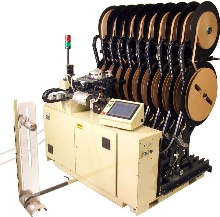

Multi-Reel Rewinder suits high-speed stamping processes.

To maximize unattended winding capacity, automatic Wyndamster 3210 incorporates 10-reel operation with side-by-side reel design. It coils any product strip up to 2.5 in. wide and accommodates reels up to 30 in. in dia. Operating at speeds up to 650 ipm, machine can function in overwind or underwind mode; complete conversion from one direction to other takes less than 1 min. Features include...

Read More »

Choosing an Optimal Riot PPE Supplier: 5 Key Factors

This ebook provides 5 key factors to choosing an optimal riot PPE supplier.

Read More »

Optical Flange Detector enhances spooling accuracy.

Optical Flange Sensing System enhances winding accuracy when used with Uhing traverse winding drives. Two versions are available: one relies on reflective properties of spool flanges, and one uses light curtain concept that does not require reflected light. Both systems employ opto-sensors to detect spool flanges and signal pneumatic or electronic switch to flip spring-actuated reversal lever on...

Read More »

Oscillating Unwinders/Rewinders accept small coil spools.

Traverse wound oscillating unwinders and rewinders accommodate small hole spools by locking them in place via conical seats on twin spindles that engage each side. Coil spools or carriers move sideways in synch with speed so pickoff or deposit point remains horizontally fixed. This results in scan wound or unwound coil without induced camber. Spindles open up to release coil, and units feature...

Read More »

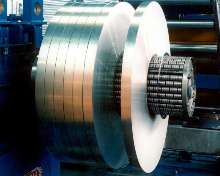

Core Slip Rewinding System provides constant coil tension.

Slip Tech system consists of core winding surface made entirely of bearings, which reduce friction between core surface and winding drum. This eliminates excess tension in individual rewound coils during build up, resulting in ability to maintain consistent coil tension because each strip is independently tensioned from core to finished coil OD. Product can also eliminate need for looping pits in...

Read More »

Multi-Spindle Winder offer max line speed of 500 fpm.

Modular Model MS 104 runs either independently or series-coupled with other modules to control entire take-up line. Each module contains 20 moving parts, and all components are accessible from front or rear of unit. With standard tension of 8-32 oz, winder handles packages weighing up to 80 lb and measuring up to 18 in. diameter and 12 in. wide. Adjustable traverse assembly and lay on roller...

Read More »

Screen Winder/Wrapper produces up to 20 rolls/min.

Model ESW-48 rewinds and wraps aluminum wire screen and fiberglass insect window screening. Cut lengths of 7-25 ft are standard. Roll widths range from 24-48 in. with finished roll diameter up to 4.25 in. Integral wrapper automatically introduces wrapping film into extended tail of roll as it exits rolling head. Overwrap shrink-film rolls, up to 54 in. wide and 10 in. diameter, can be used. After...

Read More »

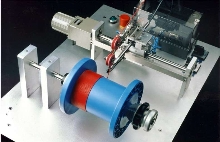

Winding System winds ferrous and non-ferrous metal strip.

Model 620 features oscillating spindle that allows material to remain in fixed position while spool moves back and forth. Accurate traverse and pitch control from 1/8 to 1Ã-½ in. minimizes camber and results in solid, damage-free wind build. System is suited for secondary operations such as single strand rewind lines or converting pancake coils into traverse wound stock, as well as level...

Read More »

Triad's JSU Series of Power Supplies Provide Robust, Low Cost Solutions

Triad Magnetics is an established leader in power supply innovation, offering product lines that span a wide range of diverse industries and applications. Adding to their long list of successful product launches, Triad announces the release of the new cutting-edge JSU Series of power supplies. To learn about all of its advantages and advanced features, see our video.

Read More »