New Laser Capabilities Recently Purchased

Weaver & Sons, Inc. is proud to announce the purchase of a new Amada Laser Cutting System.Ã- This new system will not only add greater reliability to our current laser cutting capabilities, but will also add greater speed and automation which we believe will translate into a better value to our customers, says Dyron Overton - President & General Manager.Ã- We have also added robotic...

Read More »Freudenberg Captures Sustainability Award for Unique Manufacturing Process that Reduces Engineered Waste

•Ã- Ã- Ã- Ã- Proprietary technology wins 2013 Manufacturing Leadership 100 (ML100) Award •Ã- Ã- Ã- Ã- Alternative to stamping will help Freudenberg achieve zero manufacturing waste and achieve its sustainability objectives •Ã- Ã- Ã- Ã- Process is faster, safer and eliminates up to 1,800 tons of scrap steel per machine per year PLYMOUTH,...

Read More »KTI, Inc Expands Its Laser Welding Capability

KTI has expanded its current laser welding capability by adding a state of the art CNC 2 KW Continuous Wave Fiber Laser to its E.Windsor, CT facility. This additional laser welding capacity will broaden our current laser capability and further complement our already strong Electron Beam Welding services, states Eric Welker, VP General Manager. We welcome your inquiries. Our technical staff is...

Read More »WAAG / GSE is Soaring Through the Aviation Maintenance Support Business with Breakthrough Maintenance Stand Designs and Manufacturing Techniques

Van Nuys CA - A few years ago the folks at WAAG, a Los Angeles area-based metal fabrication facility, shifted gears. They moved from innovating and manufacturing products for the aftermarket automotive world into doing the same for the Commercial Aviation Ground Support Equipment Industry. For the past five years WAAG has been building state of the art, towable, aircraft access stairs and...

Read More »

5 Reasons Why Laser Welding is the Optimal Choice For Your Next Welding Project

This white paper outlines the advantages of laser welding.

Read More »

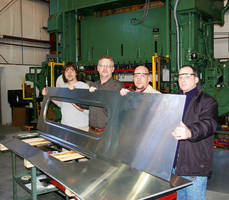

Component Engineers Inc. and New England Welding Collaborate on Project

WALLINGFORD, CT. - February 16, 2009- - Component Engineers Inc. (C.E.I.) of Wallingford, CT and New England Welding, Inc. (N.E.W.) of Avon, MA are pleased to announce their collaboration on a substantial and exciting manufacturing project. The two manufacturers are combining capabilities to complete the metal fabrication of light weight aluminum door panels. The completed door panels are for...

Read More »

Expanded Electron Beam Welding Processes

EB Industries welding job shop has provided energy beam welding services since 1965 for over 100 Fortune 500 companies, including Lucent Technologies, Applied Materials, Raytheon Systems, Dresser-Rand, JDS Uniphase, Motorola, Lockheed Martin, General Electric and Howmedica. Offering both Laser Beam Welding and Electron Beam Welding technologies allows us to attain weld depths from 0.001 to 3 in...

Read More »GraviKor Announces Landmark Partnership to Commercialize Military Vehicle Spaceframe Technology

Military and private security platforms to benefit from radical weight savings, design flexibility, and safety enhancements MADISON HEIGHTS, Mich., Feb. 5 / / -- GraviKor, Inc. today announced a strategic development and licensing agreement with Southeastern Michigan-based SpaceForm, Inc. to commercialize advanced vehicle spaceframe technology for security and military markets. The multiyear...

Read More »11,000 LB Weldment Heat Treated

Solar Atmospheres, Souderton, PA, recently heat treated two 4140 (chromium molybdenum) steel weldments, each weighing 11,000 lbs. Using a 12 foot long horizontal loading Solar Manufacturing furnace with a 50,000 lb. capacity, Solar normalized and tempered the weldments to achieve specific yield strength, while minimizing distortion, through controlled heating and cooling. The weldment dimensions...

Read More »

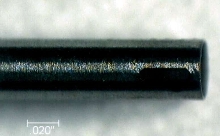

Tube Cutting/Welding targets medical device industry.

Direct Light Inc. utilizes LeeÃ-® Nd:YAG laser with CNC motion system, which provides sub-micron XY and rotary positional resolution. Parts are processed using statistical process control and x-bar/r charts, and process histograms are supplied to customers. Full service capabilities range from research and development and short-run jobs to full 24/7 production.

Read More »

Paratherm™ HR Heat Transfer Fluid: Higher Temperature Stability Leads to Longer Fluid Life

For the ultimate in heat transfer fluid performance, Paratherm offers HR Heat Transfer Fluid that is engineered specifically for closed loop liquid phase heating. When it comes to characteristics such as thermal stability and fluid degradation, Paratherm HR leads the industry in value and performance. See our video to learn how Paratherm is raising the bar for heat transfer fluids.

Read More »