Welding Station offers pre-fabrication of tube and pipe.

TIGER Welding Station allows single operator to handle 6 m lengths of tube or pipe during welding operation. Tube/pipe clamp, located on Easi-Glide X-Y slide, rotates to allow 45Ã-

Read More »

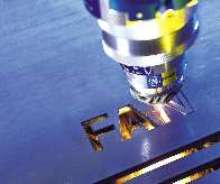

Laser Packages cut and weld machine tools.

Models C5000-E and C6000-E are carbon dioxide laser sources offering 5 kW and 6 kW power. Laser source, CNC, and servomotors are integrated and interfaced as complete system. Laser communicates with CNC via optical bus, and all laser control and diagnostics are integrated into CNC. Historical data for maintenance purposes is logged and can be accessed via CNC screen. Both laser packages can...

Read More »Welding System uses digital communication protocol.

Multi-process Power Wave-® 355M power source, with Power Feed(TM) 10M wire feeder, features push-pull aluminum MIG capabilities. It is also capable of Stick, TIG, MIG, Synergic MIG, Pulsed, and Flux-Cored welding as well as arc gouging. Unit features ArcLink-® open digital communications protocol and is rated 350 A, 34 V @ 60% duty cycle. Full amperage range is 5-425 A. Unit comes factory...

Read More »Welder delivers 10,000 peak watts.

Eagle(TM) 10,000 provides stick welding, basic DC TIG welding, and auxiliary power. Operators can simultaneously weld and use AC generator power for lights, tools, and emergency standby power. Rated 210 A/25 Vdc, unit is equipped with 2-cylinder, 4-cycle, 20 hp, OHV air-cooled Kohler gasoline engine. Welder includes 20 ft No. 2 electrode cable, electrode holder, 15 ft No. 2 work cable, and work...

Read More »

How to Properly Implement Welding Automation to Improve Return on Investment (ROI)

Learn more about the value of automated welding systems, how to calculate your automation ROI, and how to get started.

Read More »

Multi-MIG Welding Inverters monitor arc conditions.

Software-driven, Axcess(TM) 675 provides output of 675 A/44 V at 100% duty cycle, making it suited for large welds requiring long cycle times. Voltage range in CV mode is 10-44 V with 80 Vdc max open circuit voltage. Auto-Line technology enables machine to accept any primary power from 190-630 V, single- or 3-phase, 50 or 60 Hz. Auto-Axcess 675 offers same features but communicates through...

Read More »

Brazing Machine features automatic operation.

CB Lite II(TM), suited for small production runs and job shops, is equipped with repeatable PLC setup to control heat, air, and water cycle times. Able to be re-tooled and re-torched for quick application changeover, moveable machine is designed for use with rings or preforms. Unit will oscillate torches across joint or rotate part for uniform heating. Operator loads part and pushes button. All...

Read More »

Manifold Brazing Machine features automatic operation.

LB(TM) Linear Brazer automatically brazes manifolds and headers producing parts with consistent quality. It automatically senses size and position of each tube, locates joint to be brazed, and oscillates torches around joint for uniform heating. Machine optically senses correct brazing temperature and feeds brazing alloy to joint. Unit can have nitrogen purge and introduce Gasflux(TM) into flames...

Read More »

AC/DC TIG Welder delivers 200 A of welding power.

Pulling 25 A of power, Invertig 201 AC/DC TIG Welder allows users to vary AC frequency from 20-200 Hz while maintaining square wave throughout complete range for control over arc. Pulsing, with frequency from 0.4-300 Hz, is standard, and balance is adjustable from 10-90%. Unit weighs 65 lb and fits in cabinet measuring 20 x 9Ã-½ x 19Ã-¾ in. It comes with 25 ft SR-17 air-cooled TIG torch,...

Read More »

Nickel Wires allow out-of-position welds.

StoodyÃ-® 625, 182, 82, and A grades of flux cored nickel wires achieve welds in vertical-up position. Available in both .045 and 1/16 in. diameter, wires are packaged on 33 lb wire baskets. Welders can choose between running 75% argon, 25% CO2, or straight CO2.

Read More »Welding Wires have lubricating surface treatment.

SuperArc copper-coated wire and SuperGlide MIG bare wire feature MicroGuard Ultra(TM) lubricating surface treatment, which reduces spatter and creates stable arc. Treatment improves feeding by reducing friction and guards against worn contact tips and liners, plugged drive roll grooves, and kinked wire guides. It also eliminates wavy appearance that can occur as wire bumps or lurches through gun...

Read More »

Solve Any Large-scale Water Control Problem with the Aqua Dam Flood Barrier

Aqua Dam is the ultimate solution for large-scale water control projects. It combines lightweight, large size, and portability all in one innovative product. To learn more about the uses, and applications of Aqua Dam, or to see it in action, check out our new video to get all the details.

Read More »