Depaneling Vision System performs multiple tasks.

Vision system on depaneling platforms provides for consistent, accurate routing and is capable of performing fiducial recognition, edge recognition, panel and board verification, and automatic product program selection. System uses software engine and frame grabber for camera image processing and compensates for different environmental effects with adjustable lighting. Programming interface...

Read More »

Machine-Vision System enables complex assembly inspection.

QualityStation with PlantVision v7 features event-driven I/O architecture that permits multiple quality assurance inspection events to be executed asynchronously. Variety of parts and assemblies can be inspected in random order and in any lot size. Advanced machine interface (AMI) allows maintenance-level technician to configure digital, serial, or Ethernet control interfaces with virtually any...

Read More »

Machine Vision System completes test programs in 1 hr.

Optima 7210(TM) optical process test (OPT) system is designed for post-placement, inline defect detection, and process measurement. System utilizes built-in knowledge of SMD process and variation compensation. Based on Configural Recognition(TM) object recognition and image analysis technology, system provides non-contact testing with VARI-Smart(TM) image compensation software, which builds...

Read More »

Label Inspection System verifies label quality/placement.

iLabel checks for appropriateness, placement, angle, and quality of labels on bottles, boxes, cans, and packaged goods, issuing overall grade of pass, fail, or recycle for each label. Using neural network technology, product automatically learns variation in good labels and checks for flags, tears, and damage in subsequent labels. System inspects 300 labels/min with sizes from 1-10+ in. and is...

Read More »

Understanding Optical Character Recognition

Stating that OCR is most effective when used to complement linear and 2D symbols, this paper details how Optical Character Recognition (OCR) differs from barcode technology. It provides clear description of the history of OCR technology and explains the advantages and disadvantages of both data capture methodologies, OCR and barcode technology. A brief overview of some of the simplest and most reliable, common OCR fonts such as OCR-A, OCR-B, MICR E-13B, MICR CMC-7, and SEMI M12 is also highlighted. Figures illustrating examples of OCR used in a variety of applications, OCR template interface, and OCR configuration functions are included. The paper details how OCR continues to be used in broad range of application environments, from high-end machine vision to more compact, easier-to-integrate solutions.

Read More »

Machine Vision Appliance inspects quality of labels.

Requiring only minutes of setup time, iLabel checks placement and quality of labels on bottles, boxes, cans, and other packaged goods. It detects flags, tears, and damage to label, and inspects each one for significant defects then reports measurements of quality, placement position, and angle. System inspects 300 labels per minute, from 1-10 in., issues grade of pass, fail or recycle, and...

Read More »

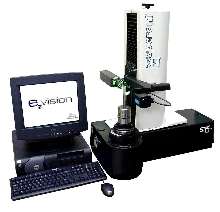

Vision System provides high accuracy and TIR.

STP-34 EzVision delivers .0003 in. accuracy at 12 in., with display resolution of .0001 in. Thermo-balanced and artificially aged pearlitic cast-iron structures ensure that equipment is isostatic and will not deform over time or temperature change. Digital tool sensing removes potential for error inherent in manual systems. System measures tool diameter up to 12 in. and tool length up to 16 in....

Read More »

Inspection System is custom designed.

Automated Inspection Machine includes EZVision(TM) machine vision system with camera optics and lighting, plus necessary material handling needed for user's application. EZVision(TM) system includes application engineering for lighting, optics, and methodology inspection setup. Mechanical configurations vary, and include vision-guided robots, feeder bowls, part-positioning tracks, conveyors, and...

Read More »

Infrared Camera includes FireWire digital output.

ThermaCAM-® S60 IR system identifies faulty components, thermal anomalies, and irregular heat patterns in devices, events and processes before critical failures. Palm-sized unit captures and stores real-time images at 60 Hz. Up to 600 real-time fully radiometric images can also be stored in camera's built-in 128 MB RAM. Camera offers both thermal and visual imaging, built-in Laser LocatIR(TM),...

Read More »Thermal Video System provides preventive maintenance.

Model TVS-7000 radiometric thermal imaging video system combines 320 x 240 microbolometer focal plane array, and 3.8 in. color LCD swivel display. Camera measures temperature differences as small as .08Ã-

Read More »

Embedded Vision System has 3.5 x 3.6 x 7.2 in. format.

LVmPC works with virtually any type of camera by using existing interfaces on internal PC motherboard or through optional frame grabber or PCMCIA adaptor cards. Up to 4 user-selected PMC add-in cards can be used simultaneously. LVmPC is 100% PC compatible and runs Windows 9x/NT/2000/XP + Embedded versions, Linux, or VxWorks. It utilizes Pentium III processor with 512k cache and Intel I815E...

Read More »

Ensure Your Medical Device Meets Regulatory Standards with Triad's Custom Magnetics

Triad Magnetics' custom components for medical devices are designed and manufactured with the strictest regulatory standards in mind. Our capabilities include rapid design, prototyping, and testing of inductors, transformers, and power supplies for medical equipment. Check out our video to learn more.

Read More »