Huffman Offers Intermittent Dress, High Q' Conventional Grinding and ATC Line Expansion

Huffman Corporation, located in Clover, South Carolina, announces it now offers intermittent dress Conventional Grinding wheels on its standard grinding platforms in addition to plated and vitrified CBN wheels. The capability can be retrofitted to installed machines. Huffman pioneered the use of CBN grinding wheel technology at its founding. For the past 30 years, the company has offered...

Read More »

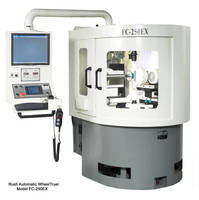

Machines process diamond/CBN wheels for grinding systems.

Designed for processing flats, angles, and radii on diamond/CBN single wheels and multiple wheel packs, Models FC-250EX and FC-700EX Automatic Diamond and CBN Wheel Truing and Dressing Machines feature PLC-controlled, automatic dressing cycles with servo-driven dressing wheel infeed, power swing, and oscillation. With wheel diameters up to 28 in., other features include ExVision, a...

Read More »

Diamond / CBN Wheel Truing and Dressing Machine

May 31, 2006--Rush Machinery will have the Model FC-250W Diamond and CBN Wheel Truing and Dressing Machine under power at IMTS 2006, in Booth #B7309. The Model FC-250W is designed for truing and dressing of flats, angles, and radii on diamond and CBN single wheels and multiple wheel packs. Use of the Model FC-250W allows for increased efficiency and accuracy by profiling, modifying profiles and...

Read More »

Grinding Wheels suit conventional, high-speed applications.

Black Magic disc wheels feature bond material that incorporates induced porosity with internal lubricants, promoting productivity in spring grinding. Reversing direction of grinding wheel every 3-4 hr minimizes dressing downtime. Featuring multiple layers of bonded cBN, cBN button wheels promote consistent finish throughout their life in spring dry grinding applications at speeds of 10,000-24,000...

Read More »

MAXPRO® High-Pressure Custom and Standard Systems

At MAXPRO® Technologies, we welcome the opportunity to design a system to meet your specific system requirements. From boosting gas pressure for molding baby bottles to scavenging helium gas from decommissioned missile tubes to research laboratories, our team of high-pressure engineers and technicians bring a wide range of experience to the table when developing solutions for your high-pressure challenges.

Read More »Vitrified CBN Grinding Wheel suits inconel grinding.

Suited for grinding hot section segments, AEROBOR(TM) removes bulk of material as well as tapers and radii and generates required finish quality. Wheel features 1.25 hr max machining time, minimal noise level, and reduced heat generation at cutting surface. With metal removal rates to 0.040 in./hr, it combines metal removal rates of CBN with dressability of vitrified wheel, leading to decreased...

Read More »

CBN Grinding Wheel provides consistent finish.

CBN Grinding Wheel features multiple layers of bonded CBN with fine grain. Spacing between matrix is filled with proprietary composition designed to wear at similar rates as CBN-bearing matrix, producing same finish throughout life of wheel. Interrupted spring end cut allows heat of grind to be dissipated faster than continuous cut. Wheel is suited for grinding stainless steel, chrome vanadium,...

Read More »

Grinding Wheels have vitrified bond structure.

Designed to work on tough metals and non-ferrous materials, Vitrified Super Abrasive Grinding Wheels include vitrified bonded CBN, PCD/PCBN, and diamond grinding wheel configurations. Tailored grinding wheels can be matched to unique specifications.

Read More »

Precision Machined Parts for High Tech Applications

For precision and value that sets the standard for quality and craftsmanship, EGS Production Machining is the source for precision and value. Our extensive capabilities and dedication to customer service allow us to deliver the optimal manufacturing solution. See our video to learn more.

Read More »