Okuma & Howa to Demonstrate Wide Range of Turning and Machining Capabilities at Eastec 2006

Okuma & Howa will be exhibiting advanced turning, milling, and machining technologies at Booth #1348 at this year-¹s Eastec show. Featuring demonstrations of the popular MILLAC 44V Vertical Machining Center, equipped with automatic pallet changer, the 2SP-150H Horizontal Turning Center, and the V100L Vertical Turning Center, O&H will bring to the floor an unbeatable combination of versatility,...

Read More »

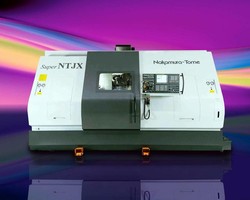

Turning Center accommodates larger parts.

Super NTJX multitasking turning center incorporates Fanuc 31iA CNC control and features more than 12 milling/turning combinations through 2 spindle motors. Generating 34.9 hp (8000 rpm) and 24.8 hp (6000 rpm) on left and right spindles, NTJX is capable of synchronized shaft/work turning with turning dia of 9.65 in.,turning length of 42.91 in., and bar capacity of 2 in. Forty-station servo-driven...

Read More »Mill-Turn Machine combines lathe and machining center.

Integrated mill turn centers in NT Series provide full lathe and machining center capabilities in one package with DCG(TM) (Driven at Center of Gravity) technology, box-in-box construction, and turret with built-in milling motor. Machines contain B-axis that uses direct drive motor, and indexing specifications allow for input by units of 0.0001Ã-

Read More »Turning Machine/Grinder machines shafts in one clamping.

Designed for hard turning and grinding of shaft and chucked workpieces, Studer S242 employs Fanuc 310i-A digital control and features modular design with digital direct-drive, 3-phase servomotors. Swing diameter is 185 mm, and between-centers grinding length is 400 mm. Able to machine parts up to 1,000 mm, unit has X- and Y-axis travels and speeds of 205 and 800 mm and 15,000 and 25,000 mm/min,...

Read More »

Your Complete Guide to Understanding & Selecting the Right Heat Recovery System

Learn about the important qualities of heat recovery systems.

Read More »

Machining Centers provide high-speed metal removal.

Millac 44V and 44H Vertical and Horizontal Machining Centers feature flame-hardened box ways, 10-tool magazine, and spindle speed of 12,000 rpm. Millac 44V offers X, Y, Z travels of 22.05, 16.14, and 16.14 in., respectively, while Series 44H features X, Y, Z travels of 16.14, 18.11, and 18.50 in. Suited for large complex part production, Model VTM-80YB provides vertical turning and milling in 5...

Read More »

Machine performs fixed and sliding headstock turning.

TRAUB series TNL is suited for long, sliding headstock Swiss-type turning, while series TNL-K is suited for short, fixed headstock screw machine type turning. Model TNL26 is offered with two 12-station turrets, 5-station end-working tool carrier, heavy-duty counter-spindle, and 5-station back-working tool carrier. Z-axis travel is ~10 in. on L-version and 4 in. on K-version. Tooling and other...

Read More »

Tooling System facilitates hard part turning.

Machining steels and alloys hardened to 45-62 Rc levels, ValEDGE Hard Part Turning System utilizes ceramic and CBN inserts as well as ValTURN(TM) ProGRIP(TM) toolholders. It is provided with T-Land corner break width and angle as well as light hone finish. For vibration-free machining, spring-loaded clamp grips insert in 2 places. Inserts, offered with 35, 55, 60, 80, and 90Ã-

Read More »

Vertical Turning Center offers self-loading operation.

Suited for automotive parts suppliers and production job shops, inverted-spindle BLUETURN 250 features turn/swing diameter of 250/320 mm, rapid traverse rates of 60 m/min, and acceleration rate of 6 m/sÃ-². It includes 12-station turret with DIN 69880 VDI 40 tool holder adapter. GE Fanuc 21i controller provides straightforward operator interface and interactive screens. Turning program can be...

Read More »

Multi-Tasking Turning Center can finish part in one setup.

Combining turning and milling functions on 4 axes, Model SKT2500MT features symmetrical head stock with built-in 30 hp spindle motor, which helps prevent heat generation. It includes 22-tool high-speed ATC and Fanuc 18ITB control with 320 m memory. For manufacturing complicated parts, tool head with contouring B-axis offers 0.001Ã-

Read More »

Turning Center features 30 hp spindle motor.

Equipped with base mounted tooling system, Model SKT 250MS offers maximum swing of 24.4 in., 15.9 in. turning diameter, and X, Z, B axis traverses of 11.4, 29.5, and 27.6 in., respectively. Main spindle features max speed of 3,500 rpm, while sub-spindle with 8 in. chuck operates at 4,000 rpm. Three-piece coupling enables heavy cutting as well as milling. Offering 0.001Ã-

Read More »

Come Alive Organics' Premium Organic Agave Provides a Healthier Choice

Come Alive Organics distributes all-natural, proprietary flavored agave for the food and beverage industry while helping children across the globe. Learn more about our agave products and our one sweet cause in this video and two-page PDF.

Read More »