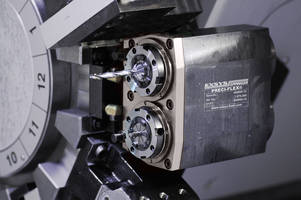

EXSYS Introduces Turning Machines and Innovative Gear Box Solutions at The Greenville Convention Center

PRECI-FLEX modular tool holding system speeds turning center tooling changeovers and improves productivity with longer tool life. DECO-FLEX tooling interface adds flexible precision for small-part manufacturing and includes holders for Star CNC brand Swiss-style machines. EPPINGER BT and BM spiral bevel gearboxes provide minimized tooth clearance and optimal transmission properties.

Read More »

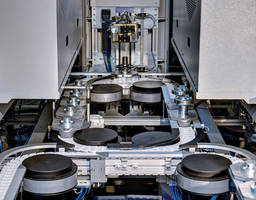

Vertical Turning DUO Cell

The machining concept of vertical pick-up machines as a modular system meets manufacturing companies' requirements for more quality, while simultaneously maintaining high flexibility and reducing cost. The right-hand and left-hand versions of the EMCO Maier VT 160 and VT 250, when linked with one of three basic conveyor options -- oval, meander, and crossover-meander designs -- provide a complete...

Read More »

PMC-Colinet Streamlines Huge Pipe Keyway Machining with Unique Angle Head from Heimatec

Ohio manufacturer of oil field equipment saves 184 hours on one high-precision cutting tool head made of NitralloyÃ-® PMC-Colinet has a long history in the pipe and tube market, having started in 1912 and introduced the world's first carbide-tooled pipe threading machine in 1958.Ã- Today, the company is established as a primary supplier of machines to the OCTG sector.Ã- Ã- Its...

Read More »

Nanotech Demonstrates Most Flexible Diamond Turning System

During SPIE Photonics West 2014 in San Francisco, Nanotech will demonstrate what has become their true flagship machining system. The Nanotech 350FG is the most diverse ultra-precision machine available. Starting with a minimum of three ultra- precision axes, it is easily expandable to five axes via optional B & C rotary axes. Typical applications for this machine include axisymmetric machining...

Read More »

Key Considerations When Choosing the Right Medical Device Development Experts: From Concept to Market

This eBook covers various factors to consider when selecting a medical device development partner to ensure proper guidance from concept to launch.

Read More »Evana Automation Completes Motoman Robots Integration Project for Leading Wheel Manufacturer

Systems Integrator also launches brand new website at evanaautomation.com EVANSVILLE, Ind.Ã- – Evana Automation Specialists, a subsidiary of Phillips Service Industries (PSI) and leading Systems Integrator and builder of custom, automated assembly and test systems, recently integrated eight Motoman robots into a new powder coating line for a leading commercial wheel manufacturer. Evana...

Read More »

KS Tooling, Inc: Turning Vendor Consolidation into an Opportunity

A number of manufacturers these days are seeing their business models shrinking, forcing them to do more with less people. Where there may have been fifteen procurement officers, there are now three. With a dramatically reduced staff looking at a list of hundreds of vendors who offer very similar services or products, there is plenty of opportunity to consolidate. In stratifying their lists, a...

Read More »

Machine Tool Runoff Cutting Titanium Confirms Advantages of 'Ultimate Tuned System'

When it comes to sourcing capital equipment for machining specialty materials, many organizations would do well to remember the 10-speed bicycle analogy. People shop and buy a 10-speed bike for recreational or workout goals, but when riding rarely go beyond two or three of the most comfortable gears. Tour de France riders and other finely tuned athletes both size and operate all their components...

Read More »

Medical Manufacturing Turns to Hardinge SUPER-PRECISION-® Gang-Tool Turning Center

Medical part manufacturing continues to be a rapidly growing market due to the large population of aging baby boomers who are looking for improved quality of life . Demand is high for high-precision components for neurological, orthopeadic, spinal/bone fixation, dental implants, drug infusion, catheter connectors, optical, maxillofacial, micro/minimally invasive, surgical instruments and other...

Read More »

Hitachi Sigma Multi-function Placement Head Brings Flexibility, High Accuracy to PCB Assembly; Exhibiting at IPC/APEX 2012

Dallas, Texas, USA- The new Sigma G5 compact, modular mounter, offered by The Production Systems Division (PSD) of Hitachi High Technologies America, Inc. (HTA) at APEX, features a unique Multi-function head that greatly enhances the system's flexibility and overall process efficiency. The head is a 3 Spindle (nozzle) head, equipped with vacuum and mechanical gripper nozzles. It can change or...

Read More »

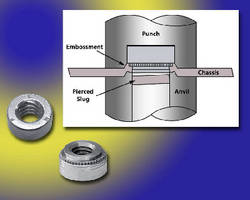

Specialized Tooling installs self-clinching nuts in 1 operation.

Integrating modified punch and anvil, PEMSERTER-® Tooling can install PEM-® Type S self-clinching nuts permanently in thin aluminum sheets without need to pre-punch mounting hole in separate operation. Raised ring on anvil allows fastener to pierce its own mounting hole and then assists in final clinching process. PEM Type S nuts with thread sizes -¼-20, 5/16-18, M6, and M8 and with -2 shank...

Read More »

More performance and functionality for Sinumerik 828D CNC

Siemens new SINUMERIK 828D ADVANCED, SINUMERIK 828D and SINUMERIK 828D BASIC sets the standard for productivity enhancements of turning and milling operations on standardized machines and simplify the automation of grinding machines. See our video to learn all about it.

Read More »