Micro Robotic Tool Changer handles payloads up to 3 lb.

Weighing less than 4.3 oz, Model QC-001 enables high-speed spider or parallel-link robots to switch end-effectors automatically. Tool changer features fail-safe locking mechanism, common lock/unlock air supply and lock/unlock sensing method, four M5 pass-through air connections, and eight 3 A/50 Vac electrical connections. Positional repeatability at 1 million cycles is 0.0004 in. With QC-001,...

Read More »

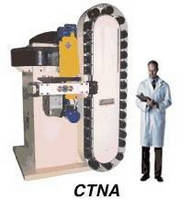

Tool Changers for CNC Machine Tools

Our extensive range of Tool Changers and Tool Storage Systems offers machine tool designers, builders and retro-fitters a simple, yet dependable and cost effective solution to accommodate multiple tooling requirements for a wide variety of CNC machine tools. With over 25 years of experience and technical know-how, our extensive range of high speed mechanical cam driven tool exchangers and tool...

Read More »Visit CJWinter and Davenport Machine at PMTS 2011 in Booth #700

Rochester, NY - CJWinter Machine Technologies and Davenport Machine will be at PMTS (Precision Machining Technology Show) located at the Greater Columbus Convention Center on Tuesday, April 19th - Thursday, April 21st, 2011 in Columbus, Ohio in booth #700. The time to invest in new technology is now. Manufacturing continues to pick-up with many new business opportunities. If your application is...

Read More »

Tool Changer is compatible with hollow-wrist robots.

Model QC-21HM Tool Changer allows for routing air and electrical lines directly through its center, and is compatible with all QC-21 Tool assemblies. It has Lock and Unlock sensing integrated into its design for safe Coupling and Uncoupling, and can be directly mounted to hollow-wrist robots. Unit features 8 pass-through air connections, in which 2 are Ã-¼ in. and 6 are 1/8 in. push-connect...

Read More »

A Solutions Provider

This white paper provides an overview of filtration and energy solutions.

Read More »ATI Tool Changers Help Bring Ford's Fuel Efficiency Message to the Masses

Ford EcoBoost Display Showing at the New York Auto Show, April 2-11, 2010 Apex, NC, - When Ford Motor Company and ABB Robotics looked to create a new live robotic display to communicate the fuel efficiency message of Ford's new EcoBoost Powertrain Technology, they turned to ATI Industrial Automation for their Tool Changing needs. Debuting at the 2010 NAIAS Detroit Auto Show and on display at the...

Read More »

Tool Changer Modules communicate via Ethernet.

Featuring integrated web server, DKD Ethernet Modules control and communicate with Heavy Automation Robotic Tool Changers using Ethernet/IP(TM) while passing DeviceNet(TM) network and power to tool-side. Modules feature Arc Prevention Circuits, which protect all electrical power contacts against high inrush current during coupling/uncoupling. Provided through connector on Tool module, Tool Stand...

Read More »

Manual Tool Changers handle payloads up to 100 lb.

Designed to facilitate tool changes by hand, Models MC-16 and MC-36 feature payload limits up to 40 and 100 lb, respectively. Model MC-16 includes 4 integrated 1/8 NPT pass-through air ports, while Model MC-36 has 6. Offering multiple fail-safe features, screw-cam locking mechanism resists vibration and prevents loosening. Units also include quick-action locking for one-handed manual operation.

Read More »New Automation Speeds CNC Tool and Cutter Grinding Cycles

10 January 2008 ANCA has developed two new automation enhancements for its GX7 resharpening machine for new levels of flexibility and productivity: a 7-station automatic wheel changer and the 85-pocket GLX automatic tool loader. With seven wheel packs, the new GX7+ tool and cutter grinder delivers new levels of flexibility for regrind shops because it can grind a wider variety of tools in a...

Read More »More Thermolock-® Shrink-Fit Tool Changers & Toolholders Available from Command Tooling Systems

RAMSEY, MN-Command Tooling Systems has announced the expansion of its ThermoLockÃ-® Shrink-Fit product line with the addition of metric BT, DIN & various HSK toolholders, 3Ã-º tapered nose extensions along with five new tool changers, making this extensive new offering of shrink-fit solutions one of the most comprehensive industry-wide. CommandÃ-® ThermoLock toolholders and extensions...

Read More »Automatic Tool Changer suits extreme industry applications.

Using Model QC-400, end effector tooling can be changed to accommodate many different styles of parts on same robot. Modular design allows user to choose from selection of optional interfaces including 4-port face seal pneumatic module or 19-pin pre-wired I/O module with standard boot that protects contact pins from fluid or airborne particulate. Model QC-400 has combined weight of 9.2 lb and...

Read More »

Solve Any Large-scale Water Control Problem with the Aqua Dam Flood Barrier

Aqua Dam is the ultimate solution for large-scale water control projects. It combines lightweight, large size, and portability all in one innovative product. To learn more about the uses, and applications of Aqua Dam, or to see it in action, check out our new video to get all the details.

Read More »